Fuji versus 3rd Party NP-W126/S

in a 12 Round Contest

“I need a new battery for my Fujifilm X-series camera. Should I buy the genuine Fujifilm OEM (Original Equipment Manufacturer) battery, or should I buy an alternative 3rd Party battery?”

With this question, you have just re-ignited a conflagration, a battle of opinions that has been raging for years. Those backing the 3rd Party Contenders, claim that you are just wasting money by buying the Fujifilm OEM battery, because the best 3rd Party batteries can deliver similar performance at a much lower price. The response from the OEM Champ’s backers, is that any monetary savings represent false economy when the other “costs” of using a 3rd Party battery are taken into account (for example, they claim that safety is compromised). Well, it’s time to finally settle this dispute. So now, get ready for the ultimate decider. But don’t expect a knock-out; this will probably go down to a points decision. Be prepared to exercise minute attention to technicalities, because in this ring, YOU will be the referee, and the ultimate adjudicator. The contest will go a distance of 12 rounds:

1 – Price

2 – Capacity

3 – Discharge characteristics

4 – Temperature management

5 – Battery swelling

6 – Power capability

7 – Self discharge

8 – Battery ageing

9 – Control codes

10 – Warranty

11 – Reliability

12 – Ultimate value

“OK, Batteries. I expect a good, clean fight.

Protect yourself at all times.

Now, return to your corners and come out at the bell.”

[ 1 ] PRICE

Price is, of course, the pivotal issue of the contest, and we could even say, the “sine qua non” issue of the fight, since if there was no price difference between OEM and 3rd Party batteries, most people would just buy OEM.

PRICE DIFFERENCES

There can be very significant price difference between the Fujifilm OEM battery and even the most costly of the 3rd Party batteries. So it is understandable that people might consider the use of alternative batteries to the OEM battery.

In the above table (based mainly on the US market), the OEM battery has been assigned a value of 100 price units, simply to make relative costs more apparent, since they can be treated as percentages. For each of the batteries listed, the current $US price is about two-thirds of the “price units” value given (except for Patona brand which is not distributed in the US, and so, does not have a regular US “street” price).

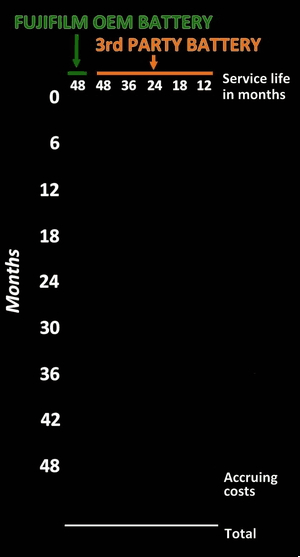

COST VERSUS SERVICE LIFE

The OEM battery supporters claim that the 3rd Party batteries don’t last as long as the OEM battery. But even if this is true, the shorter life is offset, to some extent, by the lower cost. To explore this, let’s assume that the OEM battery can provide a service life of 4 years, or 48 months (which, based on experience, is a realistic assumption). Now compare it to a hypothetical 3rd Party battery, costing 35% of the OEM battery’s cost (that would put it in the upper price group of 3rd Party batteries). This hypothetical battery’s service life would have to be reduced down to about 18 months, before it started to become un-competitive with the OEM battery, on the basis of cost. If the hypothetical battery’s service life turned out to be longer (which is likely for its price category), then the cost advantage over the OEM becomes even more compelling.

Of course, a shorter service life means that you have to purchase more batteries in order to match the OEM’s 48 months of service. This repeating battery purchase produces other effects.

BUDGETARY ADVANTAGE

Assume a hypothetical 3rd Party battery, which only costs one third of the OEM cost, but only lasts one third of the OEM life. You would have to buy a second one, and then a third one, later, to match the life of the OEM battery. In the long run, the users of the 3rd Party battery, and the users of the OEM battery, both spend the same total amount of money over the same period of time. However, the lower cost battery effectively allows the user to spread the battery costs, and pay one-third now, one-third later, and another third later still. The user may appreciate this as a significant budgetary advantage.

MORE FREQUENT BATTERY FADE PERIODS

On the other hand, frequent battery renewal, comes with a more frequent experience of transitional service, due to battery fade. In the transition period (when the battery is coming to the end of its life), the battery goes from performing acceptably, to performing unacceptably. This period can be marked by annoying, unreliable, and uncertain battery behaviour; shots per charge drops rapidly, and the possibility of unanticipated “low battery” shutdowns is increased. You might prefer not to go through this transition period any more often than is necessary. However, if the 3rd Party battery can match the service life of the OEM battery, this argument has no merit.

PRODUCTION OF WASTE

Some people say “Buy cheap batteries, and just replace them frequently”. However, if we again take the case of the hypothetical “one-third-price, one-third-life” battery, it could be argued that this battery produces three times as much waste (and three times the carbon footprint of production), because you have to buy three of them, rather than a single OEM one. In the long-term, the longest life battery (which may be the OEM battery), produces the least waste. This is an issue rarely raised, in the debate, but perhaps it should be, given our rising consciousness of environmental issues.

DELIBERATION

For the price issue, there are are reasonable arguments from both sides of the debate. But, although price differences are clear and substantial, there is a saying that “money is not everything”, and a decision based on this criterion alone, may be superficial. The implications of battery choice are multivariate, and there are other significant issues that we need to consider. We will revisit the price issue when we eventually look at ultimate value.

[ 2 ] CAPACITY

Many 3rd Party batteries seem like a great “buy” because, not only are they cheaper than the OEM battery, but they also boast a higher capacity. Unfortunately, battery capacity is a complex topic, which is often poorly understood. It is worthwhile exploring this area in some depth. Let’s try to make sense of the numbers.

The NP-W126S battery is a nominal 1260mAh (milli-Amp-hour) battery. The 1260mAh capacity is indicated by the “126” in the battery’s name, which is the capacity, with the final zero dropped. In the same way, the GFX camera’s NP-T125 battery is a 1250mAh battery (with the final zero dropped to give the name). This is Fujifilm’s current battery naming practice for these and any new twin cell (NP-Wxxx, W indicating tWo or tWin), or triple cell (NP-Txxx, T indicating Three or Triple) batteries. (Note that the naming system used for the older single cell batteries is different).

The genuine OEM NP-W126/S battery was designed around the Panasonic NCA673440 prismatic lithium-ion cell. (“Prismatic” differentiates the shape from cylindrical and pouch type cells).

There are two of these cells in each battery. For reference, this cell has a volumetric energy density of 0.47 Watt-hours per cm³, and a gravimetric energy density of 0.213 Watt-hours per gram.

Recognition of the dual cell nature of this battery will be important for understanding some of the “capacity” concepts, and will help avoid some specification misunderstandings.

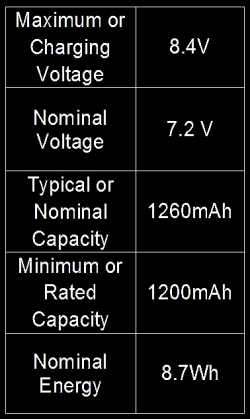

ELECTRICAL SPECIFICATIONS

The Fujifilm NP-W126S battery has 5 electrical specifications printed of its front face:

Because the battery’s terminal voltage continually reduces during discharge (going from 8.4V down to 6.0V), the battery is assigned a “nominal” voltage, which is the half-way point between maximum voltage (8.4V) and minimum discharge voltage (6.0V).

3rd Party batteries typically state only the nominal voltage, nominal capacity, and the nominal energy of the battery.

Although photographers may pay little attention to the nominal energy specification, it is required to be stated on the battery for the purpose of determining compliance with air-transport regulations, because it is a better indicator of the amount of energy that could be released in an explosive or rapid combustion event. Using the nominal energy specification, batteries are differentiated into one of three categories (less than 100Wh, up to 160Wh, and over 160Wh), in order to determine which air transport rules apply to them (for instance, how many spares a passenger is allowed to carry). Stills camera batteries are all in the lowest (< 100Wh) category. For reference, one Watt specifies a power of one Joule per second, and one Joule is equivalent to one Newton-metre.

COULOMETRIC CAPACITY

This is the specification most people think of when considering capacity. The nominal, or coulometric, capacity, specifies a current (a flow of electrical charge) which can be sustained for a one hour period of time, and is expressed in milli-Amp-hours (mAh). The NP-W126S’s 1260mAh nominal capacity can, in theory, continuously supply 1260 milli-Amps of current for 1 hour, or the various mathematical equivalents, such as, 630mA for 2 hours, or 2520mA for half an hour, etc. In practical terms, the nominal or coulometric capacity is an indicator of how much use we can expect to get from the battery before it requires recharging. In photographic terms, it will be a major factor in determining how many shots we get per battery charge. Coulometric capacity is closely related to the battery’s internal cell size (and the volume of active material contained within the cell), but it is not directly related to total battery size, since it does not take into account the number of internal cells which comprise the battery.

ENERGY CAPACITY

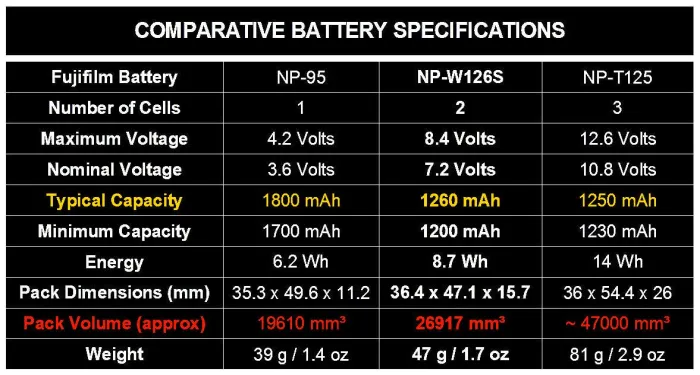

The other measure of battery capacity is the battery’s energy capacity, or nominal energy, expressed in Watt-hours (Wh). The nominal energy can be found by multiplying the capacity by the nominal voltage. So, for the NP-W126S battery, the nominal energy would be: (1.20Ah x 7.2V) = 8.7Wh. (Note that Fuji uses the minimum capacity, 1200mAh, rather than the typical capacity, for this calculation). The nominal energy is often overlooked, however it does put battery capacity into a different perspective, and also resolves the “typical capacity” anomaly that can be noticed when, for instance, comparing the three different sized batteries in the following table.

It might seem counter-intuitive that the biggest battery (the NP-T125), has the smallest “typical” capacity, while the smallest battery (the NP-95) has a significantly higher capacity. To simplify the explanation of the difference between the two types of capacity specification (energy and coulometric): one specification answers the question “How much?” (energy), while the other answers the question “For how long?” (running time). The battery’s nominal energy, expressed by its Watt-hour (Wh) rating, takes into account the voltage of the battery, and that normalises the relationship between size and “capacity”. The voltage will depend on the number of cells in the battery pack, which ranges from single to triple, for still camera batteries. The cells are connected in such a way that their individual voltages (3.6V) add together, but the total mAh capacity does not change from that of a single cell. All NP-W126 type batteries, will be twin cell, and have a reference voltage of 7.2 (or 7.4) Volts. Because the nominal voltage is a mid-point voltage, between maximum voltage and lowest allowable discharge voltage, if the manufacturer uses different end-points (specifically, a different minimum discharge voltage), then the mid-point voltage can vary. This explains why some 3rd Party batteries state their nominal voltage as 7.4 Volts. However, the 7.2 Volts and 7.4 Volts are only “indicative” voltages, and they effectively point to the same characteristic voltage.

DIFFERENCES IN MARKET CAPACITIES

The reason the Fujifilm NP-W126S battery has a nominal capacity of 1260mAh is, because that’s about the capacity limit for a battery of that size within the constraints of the current lithium-ion technology. Since the OEM and 3rd Party batteries are all the same size (they have to be, in order to properly fit the camera’s battery chamber), why do the various 3rd Party battery manufacturers specify different capacities? A survey of 3rd Party NP-W126 batteries on the market currently, has batteries ranging from 1600mAh down to 950mAh. (I did not include the claimed “1900mAh” batteries, on the basis of their lacking credibility).

There are several explanations for this wide discrepancy in quoted capacities for batteries of the same physical size:

CAPACITY TESTING CONDITIONS

In testing, the capacity may have been determined at a different discharge rate (C-rate) than the OEM battery. Since capacity varies with C-rate (an effect called capacity offset), this can lead to differences in the reported capacities. If the discharge testing is performed at a low discharge current, the measured capacity will be higher, and if performed at a high discharge current, the measured capacity will be lower. When increasing the C-rate from 0.2C to 1.0C, the capacity reading is decreased by about 10%. Capacity testing at different ambient temperatures will also cause variation in the reported capacities. For instance, a battery that recorded 1220mAh of capacity when tested at 25°C (77°F), might only record 1200mAh when tested at 20°C (68°F).

The Fujifilm battery specification is based on a discharge rate of 1.0C, at 25°C / 77°F. Full specification data sheets for lithium-ion cells (like the NCA673440) will specify the C-rate and ambient temperature at which the capacity was determined. However, similar information for the internal cells of 3rd Party batteries is, in practical terms, “un-discoverable” for most battery users.

TYPE OF SPECIFICATION

The manufacturer can have quoted either the maximum capacity, the typical (or average) capacity, or the minimum (or rated) capacity. The capacity could also be an indicative capacity based on theoretical calculations (for example, cell weight multiplied by the typical gravimetric energy density), rather than practical measurements. Most frequently, it it not stated which of these specifications is being used.

OPTIMISATION

The specific design of a battery’s electrochemistry either optimises it for Power, or optimises it for Capacity, but the battery can’t be optimised for both. The power oriented battery is able to answer demands for continuous high current (such as might be needed for shooting 4k video). In contrast, the capacity oriented battery, is able to supply low power photographic use (single-shot stills shooting, at a low rate), for a large number of shots.

Because of this difference between power optimised and capacity optimised batteries, it is possible for a 3rd Party battery to get more shots per charge than the OEM battery, but then perform poorly when supplying power for high definition video, or high frame rate, continuous shooting.

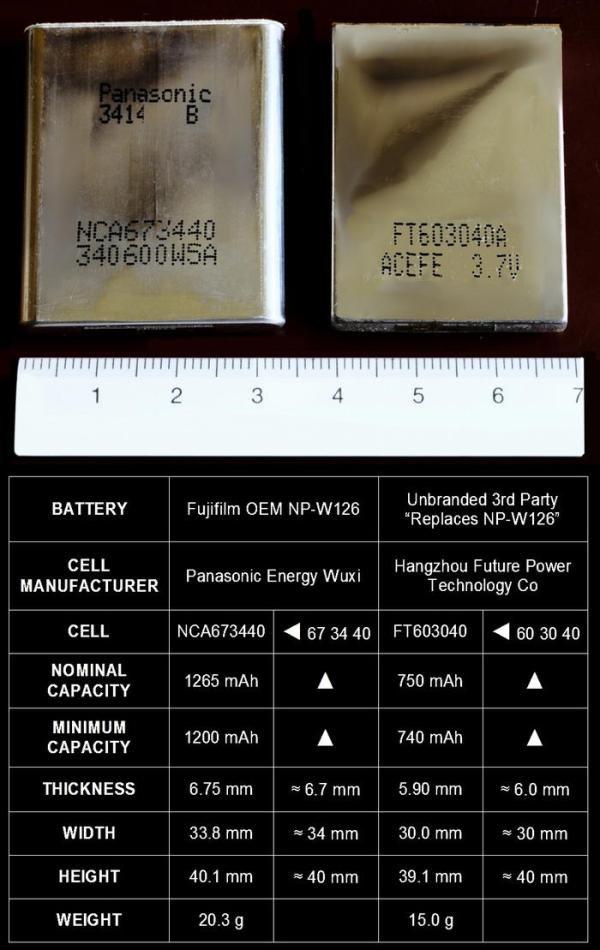

LOWER CAPACITY CELLS

A lower quoted capacity may indicate smaller internal cells, so there is less active material (the substances responsible for the electrochemical activity which produces the electricity). That reduction in the amount of active material would show up as a measurable reduction in battery weight. Note that even a slight decrease in the cell’s linear dimensions, can produce a significant decrease in volume, weight, and nominal capacity. For instance, compare the NCA673440 with the FT603040 lithium-ion cell, which appears to be about the same size:

(The chart also shows that the string of numbers in each cell name, actually indicates the approximate cell dimensions). The OEM battery weighs 47 grams or 1.66 oz (20.3g for each cell, and about 6.4g for the circuit board and case). The lower capacity battery’s weight may go down to around 40 grams or 1.4 oz (with about 15g per cell, plus a few grams of packing material, to hold the slightly smaller cells in position).

Lower stated capacities are probably reliable, since there is little market advantage to be gained by quoting a lower capacity than the competitors. One important point regarding lower capacity batteries, is that they are more likely to overheat while charging, leading to swelling. This is because the charger is typically designed to charge a 1200mAh battery, so the charging current might be higher than is optimal for the lower capacity battery.

CONFUSED SPECIFICATIONS

A 3rd Party battery producer (the battery assembler, rather than cell manufacturer), may be confused about the conventional way of determining or stating a battery’s electrical specifications. The problem is typically due to a confusion between cell specifications, and battery specifications (A battery is a cluster of cells, in the case of the NP-W126 battery, two cells). Specifically, there can be confusion over whether or not a particular specification should be doubled, due to the use of two cells in the battery.

In the first example (shown above), the stated voltage of 3.7V, is the cell voltage, where they should have stated the battery voltage of 7.4 Volts (2 x 3.7V). As a consequence, the nominal energy specification of 3.5Wh is also wrong; It should have been 7Wh. In the next example, the nominal capacity is stated as 1360mAh.

Upon opening the battery, the internal cells were found to be 680mAh capacity (from the cell manufacturers specification sheets). The battery capacity should have been stated as 680mAh, and should not have been doubled to give 1360mAh. My experience is that this error is quite frequent. Be wary of any NP-W126 type battery stating a capacity higher than 1300mAh. You will often find that they are actually half the stated capacity. However, they can still work well, even if giving less shots per charge than the OEM battery.

EXAGGERATED SPECIFICATIONS

The final reason for a wide variation in capacities is that the battery may have its specifications mis-represented, or exaggerated. At least one battery on the market boasts 1900mAh capacity, but actually delivers less than 700mAh.

Erroneous “doubling” of 700mAh would only have given about 1400mAh (still on the high side). If the discrepancy between claimed and actual capacity is significant, and intentional (with the goal of deceiving), then the battery is a fraudulent battery. There is no need to consider these un-trustworthy batteries any further.

TRADE-OFFS

If the battery is specified as a higher capacity than the OEM battery, you should reflect upon why this could be the case, and take that into your considerations. Don’t expect to get higher capacity than the OEM battery, without some other trade-offs, which could be in terms of, poorer performance under heavy loads, increased self-discharge rates, decreased battery life, etc.

DELIBERATION

Due to the reasons given above, it it typically not very productive to compare batteries on the basis of their self-quoted capacities. Also, to get battery performance that is similar to the Fujifilm OEM battery, the 3rd party manufacturer should strive to use battery chemistry close to that of the OEM battery, and so we would expect a similar (not higher) mAh capacity. Highly respected 3rd Party batteries like Watson and Patona, quote capacities that are very similar to the OEM battery’s capacity. My own experience, and that of many others, is that the best 3rd Party batteries can deliver a capacity similar to the OEM batteries. However, even with a genuinely equivalent capacity to the OEM battery, there may still be differences in power delivery rate, self-discharge rate, and ultimate rate of decline in battery’s SoH (State of Health). So, although capacity need not be a deal breaker issue for the OEM vs 3rd Party decision, it is not the only performance specification that needs to be considered.

[ 3 ] DISCHARGE CHARACTERISTICS

Discharge characteristics can be an issue, because they affect the feedback that the camera gives to the user, regarding the battery’s State of Charge (the remaining charge of the battery). This is what is indicated by the battery level display when we are using the camera. The battery level indicators of the Fujifilm X-series cameras, are calibrated for the Fujifilm OEM batteries. Because other batteries differ in their chemistry, they produce different discharge curves (voltage plotted against capacity).

Not only are discharge plots non-linear, but those typical of 3rd Party batteries also have a different shape and more prominent inflection points, in comparison to the OEM batteries. Because of this, the battery level indicator produces some anomalies when using these 3rd Party batteries.

A typical experience when using 3rd Party batteries under high power discharge situations (4k video, or high frame-rate continuous shooting), is that the charge-remaining indication is exaggerated (the actual capacity is less than what is shown), and there is little or no warning given of immanent shut-down due to battery depletion. Frequently, the indicator goes from two bars directly to empty.

For some photographers, this is both annoying, and disruptive of workflow, due to insufficient warning of power shut-downs. Other photographers just adapt, and prepare for a battery change whenever the “two bars” indication is reached. Besides, if you are not putting extreme demands on the camera, the effect is much less noticeable.

OLDER CAMERAS

If you are using an older X-series camera (pre X-T2), any display differences due to different discharge characteristics, may be a minor issue.

The older battery level display lacked resolution, and may not differentiate OEM from 3rd Party batteries in any meaningful way.

DELIBERATION

This issue does not actually affect the battery’s functionality in terms of capacity, shots per charge, or life expectancy. It might be considered as an issue affecting the quality of the user experience, and its significance, will very much depend on your personal tolerance for such technical anomalies.

[ 4 ] TEMPERATURE MANAGEMENT

Temperature management is a critical issue for lithium-ion battery safety and service condition. Although reported cases of catastrophic failure are fewer than with, as an example, notebook computer batteries, incidents with camera lithium-ion batteries do occur. Reported cases of camera battery related venting and combustion events include: A camera battery catching fire on an aircraft departing Chicago O’Hare Airport in 2013, a smoking camera battery at Raleigh Durham Airport (North Carolina) in 2017, an exploding camera battery at Orlando International Airport in 2017, and a camera battery catching fire (while charging) in Norway during 2018. Probably, most incidents occurring in a domestic context are not reported.

Extreme temperature conditions can both damage the battery, and/or render it unsafe. When being charged, lithium-ion batteries must not go outside of the temperature range 0°C to 45°C (32°F to 113°F). At temperatures below 0°C / 32°F, metallic lithium becomes permanently plated on the cell’s anode (effectively producing a loss of available lithium salts for the electro-chemical process), and ion diffusion rates on the anode are reduced. At temperatures above the upper allowable range, there is cumulative and permanent loss of capacity and reduction in charge acceptance.

If a lithium-ion battery reaches about 150°C (about 300°F), it may vent (the cell’s pressure relief valve opens, or its “burst plate” ruptures, to relieve pressure).

During venting, not only are highly flammable gases released, but electrolyte can also be released as liquid, droplets, or vapor. If venting occurs while inside the battery chamber, the battery can leak hot electrolyte fluid (containing solvents) from its terminal openings, into the battery chamber. Electrolyte leakage will be noticed as a black residue in the terminal area. In the worst case scenario, if the battery is able to reach a temperature of over 200°C (390°F), second venting and thermal runaway can occur. Thermal runaway will be the prelude to a violent incendiary event.

Because of the hazards posed by lithium-ion batteries, if operated outside of their “safety envelope”, all lithium-ion camera batteries include a circuit board for battery management and protection. Ideally, the circuitry should maintain balanced cell capacities, and guard against deep discharge, overcharging, short-circuit or over-current, and temperature range violation. The following image shows a circuit diagram representing is a protection circuit arrangement.

At a minimum, the circuit board typically uses a purpose-designed lithium-ion controller IC, combined with a MOSFET (metal oxide semiconductor field effect transistor) device for on/off switching of current.

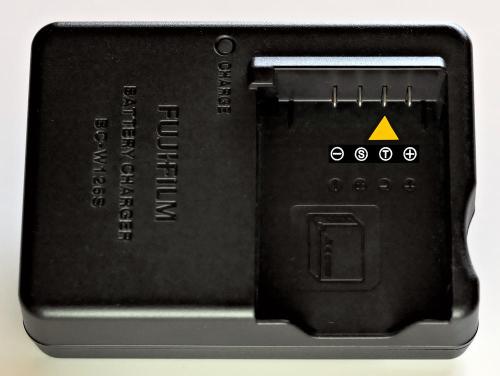

Below is shown the actual protective circuit board (which also serves as the terminal board), of an Fujifilm NP-W126 battery.

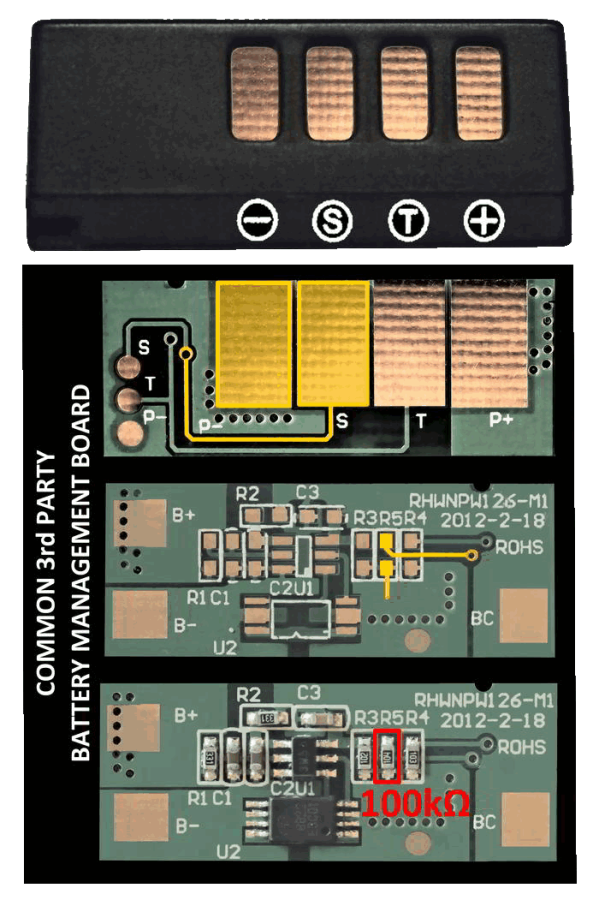

Besides the positive and negative battery terminals, the protection board for the NP-W126/S or equivalent batteries, also has circuitry connecting to [S] and [T] terminals, so that there are four battery terminals.

The [T] terminal (standing for either Temperature or Thermistor), is (or should be) integral to the thermal protection of the battery while charging.

OEM USES THERMISTOR

The Fujifilm OEM battery uses a thermistor (implemented as a tiny surface mount device on the battery’s protection circuit board), for temperature management. A thermistor is resistor whose resistance output is highly temperature dependent.

In its NTC (negative temperature coefficient) form, the resistance is inversely related to the thermistor’s temperature. NTC thermistors exhibits a large, precise and predictable decrease in resistance as their core temperature increases.

Other reasons for using the thermistor are, good tolerance to shock and vibration, and little need of output signal conditioning (just a single capacitor for ripple suppression). The small size of the NP-W126/S thermistor (less than 1mm long), gives a low thermal mass, resulting in minimal lag for measurement of rapidly changing temperatures. The thermistor outputs a 10kΩ (kilo, or thousand, Ohm) resistance at a temperature of approximately 25°C (77°F). A reduced resistance indicates an elevated temperature, and vice-versa. The [T] terminal of the BC-W126S charger (or the camera, if utilising in-camera charging) reads the resistance on the battery’s [T] terminal, and is able to determine the battery’s internal temperature, and decide whether it conforms to the safe-charging temperature limits. Charging is terminated if the battery temperature goes outside the safe range.

NO THERMISTOR IN 3rd PARTY BATTERIES

Although it would seem reasonable to assume that 3rd Party batteries would implement this same thermistor driven system of charge-temperature management, it is generally not the case. 3rd Party batteries generally do not employ a thermistor. However, simply omitting the thermistor is not really an option, because the Fujifilm chargers (and cameras capable of in-camera charging), will not allow charging to initiate, unless a resistance indicating a temperature within the safe operating range, is found on the battery’s [T] terminal. (You can verify this by placing a small piece of tape over just the [T] terminal of any “NP-W126” battery, and trying to charge it in a Fujifilm charger, or by using in-camera charging; charging will be blocked). In order to fulfill this “valid resistance” requirement, the 3rd Party batteries typically use a simple fixed-value, 10kΩ resistor in place of the thermistor circuit. The fact of the 10KΩ resistor substitution, is verified, not only by measuring resistance at the [T] terminal over a wide range of temperatures, but also by “cracking-open” various 3rd Party batteries, and examining the circuit boards. Note that the charger (or camera) is unable to tell whether the resistance being read is output from a thermistor or fixed value resistor. If you have an understanding of printed circuit boards and know what a “via” (vertical interconnect access) is, you will be able to trace the 3rd Party battery “T” circuit on the following image.

The result of using the 10kΩ fixed-value resistor, is a battery which tells the charger or camera, that the internal battery temperature is a very acceptable 25°C (77°F), regardless of the actual battery temperature, and even if the actual temperature is outside the safe range. Although precision grade (limited variation from the nominal specification) and aged (which reduces the tendency to “drift”) thermistors can be costly, it is probable that using a resistor rather than a thermistor, also has some fabrication and assembly advantages for the 3rd Party battery maker, besides cutting component costs.

CONSEQUENCES OF NO-THERMISTOR

Likely consequences of not implementing the thermistor circuit are that, each time the charging process transgresses the allowed temperature range, the battery sustains some cumulative and non-reversible damage. Its performance might decline (and a corollary of this would be a reduction in service life), and the battery may eventually begin to swell, due to internal pressure caused by the over-heating, with the possibility of becoming stuck in the camera’s battery chamber. Less-likely (based on the relative infrequency of reports) but more extreme consequences are the battery catching fire or exploding.

TEMPERATURE MANAGEMENT AS A SYSTEM

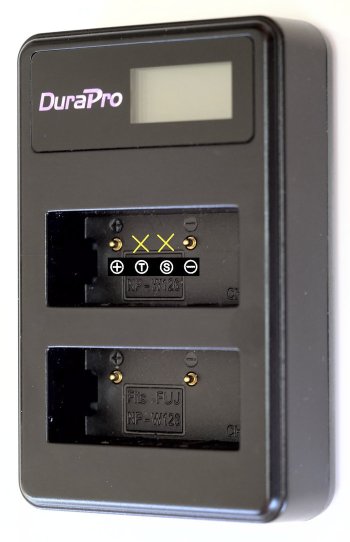

Does that mean that by using an OEM battery, my charge process is always temperature protected? Actually, “No”. Importantly, thermistor temperature management is a system, which not only requires the battery’s ability to send its temperature information, but also the charger’s (or camera’s) ability to read and interpret that temperature information.

So, if you have a Fujifilm OEM battery (with thermistor), but you are using a 3rd Party charger with no [T] terminal, the thermistor data is virtually useless, because the charger has no way of reading it. If you are using a USB charger (which Fujifilm does not offer), you may notice it has no [T] terminal, and therefore there will be no temperature management advantage by OEM batteries over 3rd Party batteries, despite having a thermistor.

An exception to this, is the Nitecore FX1 dual (the second battery bay is on the underside) USB charger, which does have a [T] terminal, to monitor the thermistor readings. However, protection, in this case, is not automatic. The FX1 charger will report the correct temperature of a thermistor equipped battery, but it does not terminate charging if the battery goes outside the 0°C to 45°C allowable charging temperature range. The user needs to stop the charging process if they notice that the temperature display is approaching the 45°C charge temperature limit. [Thank you to Michael Kluth, who provided further valuable information regarding the FX1 charger’s operation].

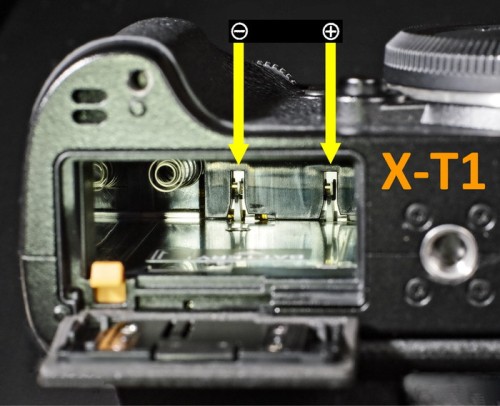

However, in-camera or in-grip charging, always accesses the [T] terminal, which is why older Fujifilm cameras like the X-T1, which only had two battery terminals in the battery chamber, could not have implemented in-camera charging.

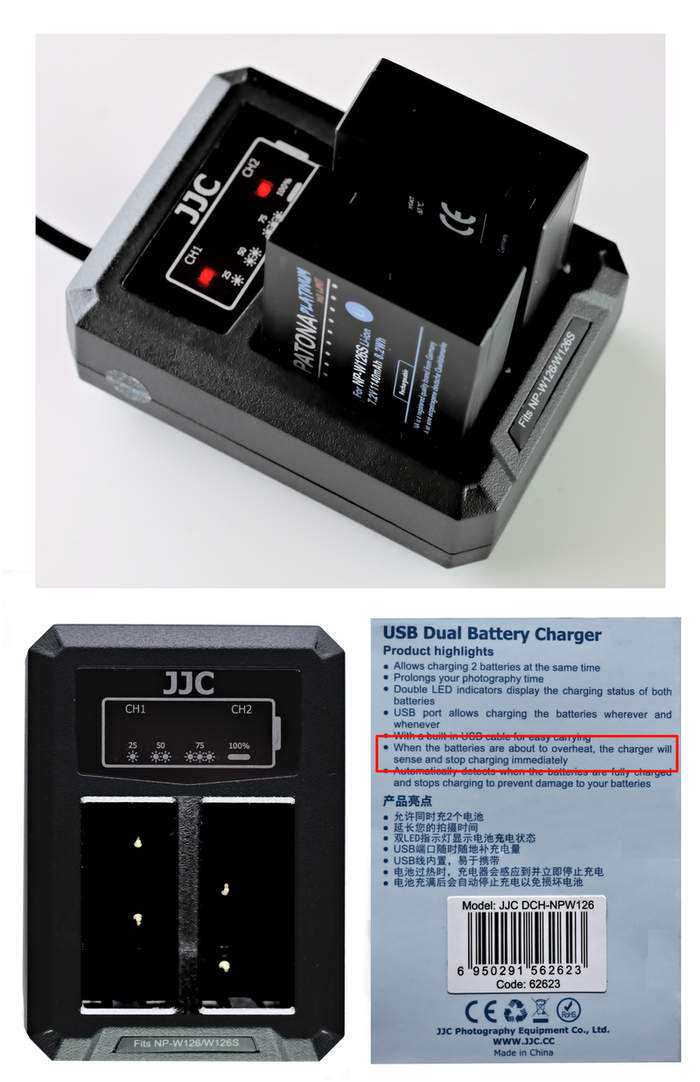

If you are using a two terminal ( [+] and [−] only ) charger, then the having or not having a thermistor by the battery, becomes an irrelevant factor. On the other hand, the JJC DCH-NPW126 USB dual charger has a temperature sensor built into the body of the charger, and this should extend over-temperature (but probably not under-temperature) charge protection to all batteries, whether they have a thermistor or not.

The Watson Duo Charger also states in the Owner’s Manual (page 5), that it provides overheat protection: “The Duo Charger senses when the battery is about to overheat and immediately stops charging”.

Once again, the heat sensor must be built into the charger, because the battery mounting plates do not have contacts to read a thermistor built into the battery. (There may be other chargers with built in temperature sensor, but I am unaware of any verified alternatives, at the moment).

The charge temperature management that you get (or don’t get), depends on your combination of battery and charger setup. By selecting an appropriate battery-and-charger combination, you can ensure protection from over-heating, even when using 3rd Party (no thermistor) batteries.

COLD CLIMATES

If you are living in a very cold climate, and you are not using high C-rate charging, battery over-heating while charging may not be an issue. It is normal for the battery’s temperature to rise by about 5° of the Celsius scale, or 9° of the Fahrenheit scale, during moderate C-rate charging. In very cold conditions, the battery’s temperature might be able to rise by several times that amount, without getting close to the upper limit for charge-temperature. In cold climates, your main problem may be to ensure that you do not attempt to charge the lithium-ion battery at freezing or sub-freezing temperatures (which will severely damage the battery, due to lithium plating).

HIGH CHARGE RATES

Batteries become hotter when charged using high currents, so charge rate is relevant to temperature management. C-rate specifies the limiting current during charging or discharging of a battery. The C-rate is the ratio between capacity (in milli-Amp-hours) and current (in milli-Amps), normalised against a time period of one hour. So if we use a 1200mA current to charge a 1200mAh battery, (a ratio of one to one), the charge time would be (in theory), one hour, and the C-rate would be 1C. If we used 600mA of current to charge the same 1200mAh battery, the time taken would be two hours, and the C-rate (only half the charging efficiency of the first case), would be 0.5C. Please note that, during the second half of the charge process (the saturation phase), the current rapidly drops below the value represented by the nominal C-rate, so you cannot accurately calculate charging times, based solely on the C-rate.

For a 1200mAh battery, 0.7C or higher is considered a “high” C-rate, which would indicate a charge current of about 840mA, or higher. It is generally not advised to charge batteries of the NP-W126/S type, at C-rates higher than 0.7C (although the Fujifilm BC-W126S charger can output 0.75C, compared to the 0.6C of the previous BC-W126 charger). Most of the regular (not-fast) chargers use a C-rate of about 0.5C (so, current value is half the capacity value), which gives a charge current of about 600mA. In comparison, the Nitecore FX1 charger is rated at a maximum output current of 1000mA, and so it would be considered a “fast” charger.

This high charge rate is possible because because the user can monitor the temperature on batteries that have a thermistor. (But what if the battery doesn’t have a thermistor, and so tells the charger that it is 25°C, regardless of its actual temperature?)

DELIBERATION

On the issue of charge temperature management, the battery cannot be considered in isolation from its intended method of charging. If you are considering a setup that does not implement charge-temperature management, you should satisfy yourself that the risk of battery swelling, or even of a catastrophic-failure type charging event is minimised and acceptably small.

[ 5 ] BATTERY SWELLING

Battery swelling is a common phenomenon with some 3rd Party batteries. However, it is virtually unknown with properly charged and used Fujifilm OEM batteries. The several cases I know of, where the “Fujifilm” battery was reported to have swollen, each turned out to be a counterfeit battery.

CAUSES OF SWELLING

Swelling, where the central thickness of the battery noticeably (and permanently) increases, indicates that the battery has been overheated, usually during charging. Overheating produces gasses, mainly hydrogen and carbon-dioxide, as well as carbon monoxide and ethylene (C2H2) from reduction of the ethylene-carbonate electrolyte. This evolution of gases increases the internal pressure of the two prismatic cells, and causes deformation tending towards a spherical form, because the round shape distributes the pressure induced stresses more uniformly. Because there are two prismatic cells, there are four significant deformation surfaces. Upon cooling however, the external to internal pressure gradient is insufficient to return the cells to their original flat shapes.

TOLERANCES

The NP-W126/S battery fits the X-cameras by fairly narrow tolerances (less than 5%). On the X-T3, the battery’s fit to the battery chamber allows about 0.5mm (20 thousandths of an inch) of “play” in the dimension sensitive to swelling, to allow for easy insertion. That play is equivalent to about 3% of the battery’s nominal thickness.

In comparison, a heavily swollen un-branded battery that was assessed, exceeded the chamber width measurement by 0.4mm (16 thousandths of an inch), giving about 6% increase to the central thickness.

There is enough structural “give” in the battery chamber that, by pushing firmly, you would be able to fully seat the swollen battery, (which would “wedge” its way in, because the battery’s ends are typically not swollen, only the centre). However, the battery will not easily release, and you may have to resort to heavily striking the camera against your hand (“inertia” release), a damaging use of tools (“extraction” release), gluing a tab to the end of the battery (“adhesive” release) or even having to partially dismantle the camera, to get the battery out.

EFFECTS OF SWELLING

A swollen battery poses the following problems. If inserted into the camera’s battery chamber, it may become difficult to remove, and there is the risk of damaging the battery chamber in attempting to remove the battery. If the battery swells significantly while inside the battery chamber (this could happen if you are utilising in-camera charging of a “resistor instead of thermistor” type battery), the battery could stress, bend, or crack, the chassis and circuit boards that either form or adjoin the walls of the battery chamber. However, even if the battery does not cause camera damage, a swollen battery will continue to decline, not only in capacity but also in safety, and needs to be (properly) disposed of.

EXPANSION

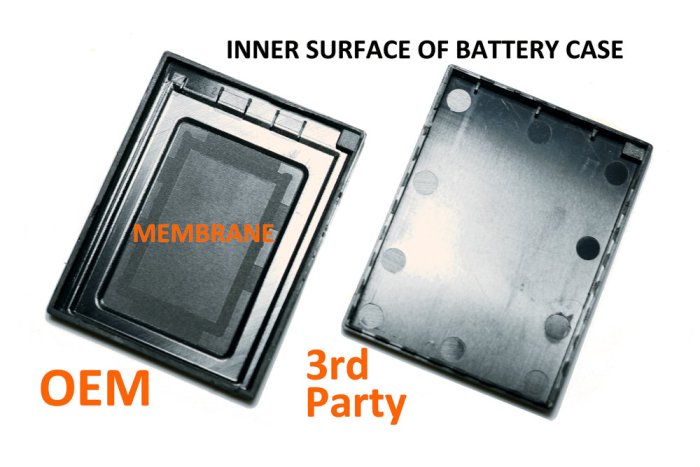

Although the Fujifilm OEM battery is reputed not to swell, it is natural for most substances to expand when they are heated. Because the battery’s internal cells are sealed, we would expect some (even if extremely slight), “expansion” during the normal charge process. The OEM battery has a construction which is able to manage this. The two faces of the OEM battery’s polycarbonate case (and the internal cell separator) are actually membranous.

The centre thickness of this flexible membrane is only 0.25mm (9.8 thousandths of an inch). It’s thin enough that light will pass through it.

As well as this, the membranous surface is concave (curving inward) in shape, with the centre of the faces shallower than the edges of the case, by about 0.3 mm on each side.

This thin and flexible construction gives a case that is able to expand slightly in its middle thickness, without actually altering the nominal specifications. Therefore, any slight expansion (not enough yet to be considered “swelling”), by the OEM battery, can be accommodated. The practical difference between expansion and swelling, is that expansion is reversible (the deformation to the cell case has not exceeded the case material’s elasticity yield-point), while the deformation of swelling has “passed the point of no return”. In theory, the OEM battery could expand by up to 0.6 mm in its middle thickness, and still maintain the full 0.5mm “play”, and without making any difference to the battery’s fit in the chamber, or to its ease of ejection.

DELIBERATION

The risk of battery swelling is one of the main arguments used by the proponents of the “only use OEM batteries” position, and for some people, is a deal-breaker with regard to using 3rd Party batteries. However, that risk may be mitigated by, over-heat protection while charging, avoidance of in-camera charging, living in a cold climate, and your own careful attention to the condition of the battery, and to any changes it displays. Also, check on-line forums for whether a particular brand of batteries has a reputation for swelling (some do).

[ 6 ] POWER CAPABILITY

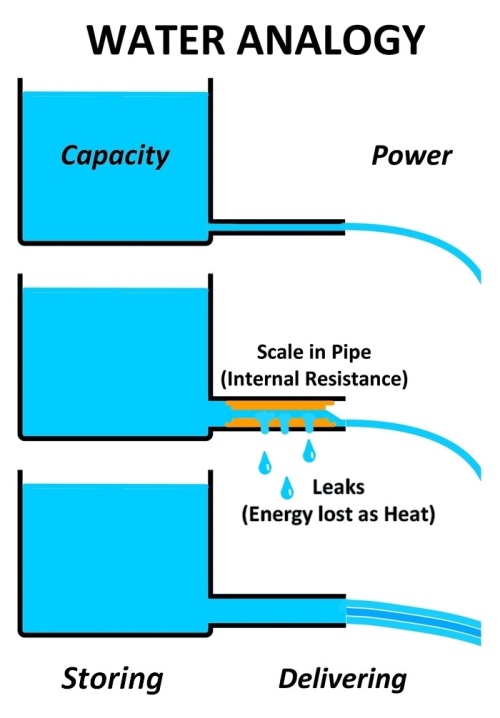

Whereas energy capacity (in Watt-hours) is concerned with the battery’s capacity to store electrical energy, power (in Watts) is concerned with the ability to deliver that energy, for use. The ideal is that all of the released energy should be available to power the camera, but due to various inefficiencies, some energy is always lost as heat.

In the following, the ability to release high usable power, while limiting heat related losses, will be referred to as the performance level of the battery. The Fujifilm X-series camera batteries have evolved from a standard performance level (the NP-W126) to a higher performance level (the NP-W126S battery). The newer NP-W126S battery, replaces the NP-W126, even though its higher performance level is not required by the older (pre-XT2) X-series cameras. Importantly, there is no difference between the two battery types, in either energy capacity or coulometric capacity, since this performance issue is related to battery heating, and the battery’s rate of power delivery.

PROPRIETARY INFORMATION

How the battery’s manufacturer, Panasonic Energy, was able to realise the performance increase, is proprietary information. However, the problem that they addressed would typically have involved one or several of the three electrochemical overpotentials or polarisations (activation polarisation, concentration polarisation, and ohmic polarisation) which reduce a battery’s power efficiency, and ultimately lose electricochemical energy as heat. Considering that the physical and electrical specifications of the type “S” battery remain unchanged from the original, the improvement strategy most likely involved the use of electrolyte additives to improve the battery’s electrochemical efficiency. Whatever the precise improvement strategy, such information is rightly considered an industrial secret, so it is not a situation where the competitors can simply copy and apply the same solution.

“S” VERSUS “NON-S”

In practice, the higher performance “S” battery can work at power levels where the standard performance battery might not be able to keep up with the power demand. The standard performance battery’s failure to meet that demand, may even trigger a camera lock-up event.

In order for the latest high-performance cameras to know whether the loaded battery “can deliver” in these high demand situations, the batteries have a way of “signalling” their class of performance level. This information is supplied over the battery’s [S] terminal. After assessing the type, the camera indicates the type to the user, by way of alternative colours (yellow or white) for the battery level indicators, and by way of a possible advisory message at power-up time, on cameras where the difference matters (such as X-H1 and X-T3).

YELLOW OR WHITE

When a battery is loaded into a capable high-performance camera (X-H1 or X-T3), the camera interrogates the resistance on the [S] terminal of the battery. If the resistance is 100kΩ, the camera determines the battery to be either an OEM NP-W126 battery, or a 3rd Party equivalent, and the battery level display is in yellow. However, if the resistance shows as 680kΩ (thus exceeding a set resistance threshold), then the camera determines the battery to be an enhanced power delivery capable NP-W126S battery, displayed in white.

In this second case (NP-W126S), I did not say, “or a 3rd Party equivalent”, because it is still uncertain whether there really are 3rd Party batteries that can provide the same performance level as the OEM NP-W126S battery. Definitely, 3rd Party batteries are coming onto the market, claiming to be NP-W126S equivalents, and even registering as such when inserted into an X-H1 or X-T3 camera, however, there is more to this than meets the eye.

“S” RESISTANCE

The original OEM NP-W126 battery showed a 100kΩ resistance at the [S] terminal, so the power management boards of 3rd Party batteries implemented a 100kΩ resistor to give the same reading on the [S] terminal as the OEM batteries did. That made sense, because the 3rd Party batteries were intended to be an interoperable alternative to the OEM batteries.

Now, however, we have a situation where the OEM type “S” battery (with enhanced performance) gives a 680kΩ resistance at the [S] terminal, which indicates that it is a type “S”. The problem is, the manufacturer of a non-OEM battery (still using the previous, standard performance chemistry), can substitute a 680kΩ resistor for the the protection board’s 100kΩ resistor (or simply omit the resistor, and leave the [S] terminal open-circuit). A battery with the appropriate [S] terminal resistance can pass itself as a high performance version, although the only thing changed was the “signalling” resistor.

EASILY MANIPULATED

You can verify that the type “S” indication can easily be manipulated, by placing a small piece of tape over just the [S] terminal of a “non-S” type battery (either OEM, or 3rd Party). This makes the [S] circuit an “open circuit”, and changes the resistance to a virtual “infinite resistance”, which (by definition) exceeds the set resistance threshold for type “S” indication. Insert the battery into an X-H1 or X-T3 camera, and, Voilà! Now the battery registers as an NP-W126S battery, it shows a white battery level indicator rather than yellow, and the several seconds duration “PLEASE USE NP-W126S BATTERY, etc” advisory message does not display, even though the battery has the chemistry of the standard performance type.

RELIABILITY OF “S” INDICATION

Fujifilm cameras are designed to be used with Fujifilm OEM batteries, and the purpose of the [S] terminal reading is to differentiate between different types of Fujifilm OEM batteries, not to differentiate between OEM and 3rd Party batteries. So the [S] terminal implementation gives reliable information when Fujifilm OEM batteries are used. But, the “S” indication cannot absolutely be relied upon when 3rd Party batteries are used. Just because the label on a 3rd Party battery states that it is an NP-W126S equivalent performer, does not mean that it is. And just because a 3rd Party battery registers in an X-H1 or X-T3 camera as an NP-W126S, does not mean that it will give equivalent performance to the OEM battery. Although 3rd Party manufacturers may be able to boost their battery performance to be equivalent to the OEM NP-W126S battery, the “equivalence” will depend on their performance, not on their in-camera battery indication. As an example of this unreliability, note the anomaly displayed by this pair of, otherwise identical, batteries:

A 3rd Party battery’s “S” designation, is not a reliable indicator of its performance. It may be higher performance, or it may just be print and electronically labelled as such. At the moment (early 2019) I am inclined to ignore any 3rd Party battery’s claimed “S” designation, and rely on my own assessment of the battery’s performance.

DELIBERATION

It is not proven yet, that non-OEM batteries are able to achieve exactly the same power delivery rate as the Fujifilm OEM battery, and type “S” claims on 3rd Party batteries should be treated with caution. However, inability to achieve true type “S” performance may not be relevant, if you don’t actually need it. Type “S” performance is not required by all X-series cameras, and Fujifilm even states that the cameras prior to the X-T2 will not benefit from the higher performance level. Furthermore, even if you have a camera which can benefit from the performance improvement, your own shooting style may not. If you use your camera mainly for landscape photography, for example, you are unlikely to require that performance level. If you don’t shoot 4K video, if you don’t use high rate continuous shooting, and if you don’t have continuous auto-focus turned on all the time, you probably don’t require the higher performance level. Remember, the standard performance level does not mean that you get less capacity.

[ 7 ] SELF DISCHARGE

Even without being used, a battery is always in a state of running down. All batteries are subject to a deficiency known as self discharge. An elevated level of self discharge is experienced as a charged battery which is unable to retain a high level of charge over a period of days or weeks, when not being used. The cause is an internal current flow called leakage current. Part of the leakage is due to inefficiencies in the battery’s electrochemical makeup, and part is due to leakage through the protection board’s circuitry. Self discharge is also highly dependent on ambient temperature, with higher self discharge rates occurring at higher ambient temperatures. Exposure to temperatures beyond the normal operating range (ie, above 45°C / 113°F) will increase the battery’s future self discharge characteristics, even at normal temperatures. A low rate of self discharge is a desirable quality in a battery. A commom criticism of 3rd Party batteries is that their self discharge rate is higher than that of the OEM battery. Please note, that a battery installed in the camera body, will experience increased discharge while not being used, due to stand-by current (while awaiting a power-up signal from the camera’s on-off switch), and due to powering the cameras clock-calendar. This is discharge by the camera, rather than self discharge.

BENCHMARK

A normal rate of self discharge after full charging, would be 5% loss in the first 24 hours, and a further 5% loss (2% intrinsic and 3% due to the battery’s management board), over the rest of the month. So at the end of one month, the battery should still have 90% of its fully charged capacity.

MEASUREMENTS

A standard method for measuring self-discharge is to perform a standard charge, store the battery for 30 days at 25°C±0.5°C, and then perform a standard capacity test. Because there is a relationship between open circuit voltage (the voltage you would measure when the battery is not in the camera) and State of Charge (the capacity remaining), an alternative method is to to monitor a battery’s open circuit voltage (with a digital multi-meter), at regular intervals over a period of days and weeks. A good result would be approximately 14 milliVolts decrease per day, after the first 24 hours.

DELIBERATION

Because self discharge reveals itself over time, photographers who charge their batteries just before use (so there is no interim period between charging and usage), may not be affected by moderate degrees of self discharge. However, in advanced cases, the loss of charge may be noticeable over a period of hours. Battery self discharge is a fact of life. The question is whether the 3rd Party battery can equal (or perhaps even better) the low self discharge characteristic of the Fujifilm OEM battery.

[ 8 ] BATTERY AGEING

All batteries decline in their capabilities over time, and eventually reach a point where their ability to perform does not meet the user’s needs. In other words, batteries age and die (or at least, start to give unacceptably low performance). This process consists partly of a time driven element (calendar fade), and a usage driven element (cycle fade). A common criticism of 3rd Party batteries is that their service life is shorter than that of the OEM battery.

CALENDAR FADE

Even if you never use the battery, it has a limited calendar life. As a general rule, the capacity of an unused battery will reduce to about 80% by the time it has reached two years of age. However, because you are probably using your batteries, rather than keeping them in extended storage, cycle fade (which accompanies battery usage), will be of more interest to us.

CYCLE FADE

A battery’s charge retention steadily declines through successive usage cycles over a period of months or years. One whole cycle refers to one charge period plus the following discharge period. The typical test condition is fully charging at 0.5C to a voltage of 8.4V, and then, discharging at 0.5C to a voltage of 6.0V. The cycle life is the number of cycles which can be made before the discharge falls below a set percentage of the rated capacity. A reasonable expectation (for mirrorless camera batteries), would be about 80% capacity after 300 cycles, and 70% capacity by 500 cycles.

It is difficult to assign a time-frame to cycle referenced usage, since this will differ according to the particular photographer using the battery. Fujifilm states that the NP-W126S battery should be good for at least 300 cycles. On the basis of this 300 cycle expectation, if you charged and ran down your battery every day for six days of every week, the battery would barely last one year, before hitting the 80% mark. However, a photographer with such heavy battery usage, is likely to have more than one battery, (with some batteries being charged while others are in use), so that in practice, you may still find that it takes more than 2 years for an individual battery to reach 300 cycles.

The 300 cycle specification does not mean that at 300 cycles, the battery is “dead”; rather, it means that by 300 cycles, because the battery only retains 80% of its original capacity, it may no longer be performing up to the photographer’s expectations. For example, on a shoot that could normally be completed on one fully charged battery, you may now have to do a battery change before the end of the shoot, if the battery is showing signs of cycle-fade.

BENCHMARK

As a service life benchmark, an OEM Fujifilm battery can be expected to give four or five years of service. About two years of primary service (top capacity and performance, suitable for professional needs), and about two to three years of secondary service (declining, but still good, capacity and performance, suitable for more casual photography, or for back-up use). The service life has effectively ended when the battery gives an unacceptably small number of shots, or it just won’t hold a charge. When comparing 3rd Party batteries to OEM, we should frame the comparison within the context of the four to five year lifespan of the OEM batteries.

DELIBERATION

Because battery ageing takes place over a period of at least months, it is not something that you can assess instantaneously, or within a short period of the purchase time. You mainly get this information from your own extended usage experience, or that of others. Comments such as “I have been using this battery for a while, without any problems”, are unfortunately, so imprecise as to be virtually useless. More objective feedback with reliable numbers (such as months of service, charges per month, and typical number of shots per charge), from other battery users (either colleagues, or via on-line forums), is invaluable in making a pre-purchase assessment. Again, the question is whether the 3rd Party battery can equal (or perhaps even better) the long service life of the Fujifilm OEM battery.

[ 9 ] CONTROL CODES

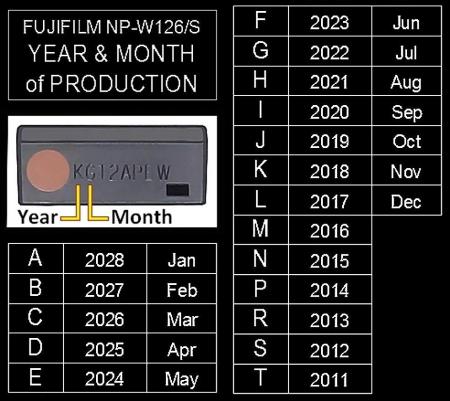

Control codes (or production codes) are an important part of battery manufacturing quality assurance. Although there may be codes on internal components of the battery (and therefore, not visible to the user), the codes of interest to the user, are any codes marked on the case of the assembled battery.

These sequences allow the manufacturer to track such details as a battery’s date of production, production batch, production line, region of destination, or other pertinent information. If a battery is found to be faulty, with a systemic fault that may affect other batteries of the same production batch, these codes are necessary to be able to distinguish affected batteries from the rest of the production cohort.

RECALLS AND ADVISORY NOTICES

Control codes allow after sales follow up, in cases where a product batch has been found subject to quality issues. These do happen. In February of 2012, Nikon initiated a voluntary replacement scheme, for specific batches of their EN-EL15 batteries, due to the possibility of the the battery overheating, and the exterior casing becoming deformed. Such a replacement scheme is only possible, because batteries from the affected production batches can be identified, by way of their lot numbers.

PRODUCTION DATE

A cheap battery may turn out to effectively be an expensive battery, if you find that you purchased stock that is several years old. Even though it has never been used, it may now be past its prime, due to calendar fade. Lithium-ion batteries are at their best for about two years, post manufacture. After that, a decline in performance starts to become apparent. With many 3rd Party batteries, their age since date of production is generally not discoverable, and we have to make assumptions about age based on their purchase date. A feature of the Fujifilm OEM batteries is that their production date can be precisely determined.

This is useful, not only for projecting future performance expectation, but also for avoiding overly-old batteries at time of purchase. (Taking into account distribution and logistics matters, up to several months past the production date would seem an acceptable age for a “fresh” battery).

DELIBERATION

Control codes can contribute to our level of confidence in the battery, and as such, can deliver a user-experience type advantage. It affects how you feel about your new battery acquisition in terms of confident expectation that this is a quality battery, with a probable long service life. If it is important to you to ensure that newly purchased batteries are as fresh as possible, and if you can inspect the battery before purchase, OEM batteries, because they can be accurately dated, may have an advantage. Without the ability to date the battery, 3rd Party batteries may have a degree of chance attached to their purchase, especially if the vendor has a low or unknown turnover rate.

[ 10 ] WARRANTY

There are two different warranty issues. One is the warranty on the battery. For the OEM battery, this may only be several (maybe 3) months, depending on your regional Fujifilm office. Among the 3rd party providers, you can find a few that offer a clearly spelled out warranty (in one case, 3 years). But for most of the 3rd Party providers (particularly unbranded, or little know brand batteries), there may be virtually no warranty. The battery’s vendor might replace an early failure battery, but mainly as a matter of goodwill, and to preserve good feedback.

CAMERA WARRANTY

The other warranty issue is to do with how using a particular battery could affect the warranty on the camera. If a camera, still under warranty, was damaged due to a defective battery, the camera company would rightly be concerned with the question of whether the battery was an OEM or a 3rd Party battery. Firstly, if the battery was the cause of the damage, the responsibility for the damage should lie with the battery manufacturer, who would not be the camera company, in the case of a 3rd Party battery. Secondly, the camera company typically abnegates responsibility in cases of “failure to follow operating instructions”, including the instruction not to use any batteries other than the OEM battery.

For some people, buying an OEM battery, is like paying extra to get insurance, so that they won’t have to cover their own repair costs if a defective battery induced problem should occur, while the camera is under warranty.

EXPIRY OF WARRANTY

The warranty issue could be considered a short term, and a transitory issue. Eventually, the warranty on the camera expires, and It could be argued that, if the camera is out of warranty, then the warranty issue is not relevant. This would generally be considered a reasonable position to take. However, if you up-grade your camera regularly, then long term considerations can make this situation a little more complex.

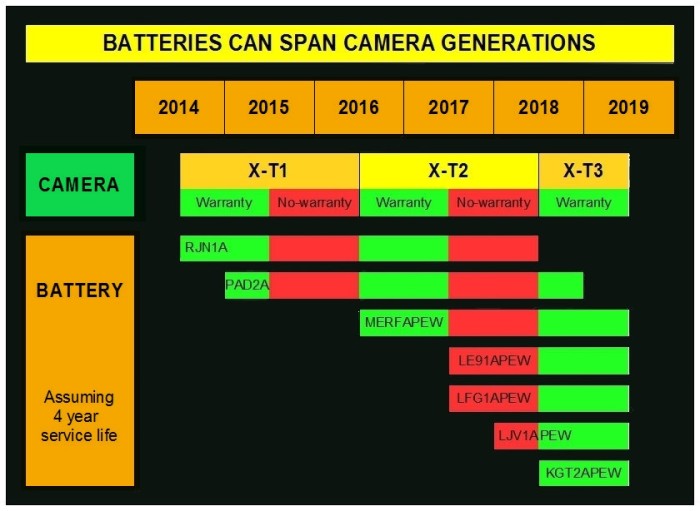

BATTERIES CAN SPAN CAMERA GENERATIONS

Of course, a new camera comes with a new OEM battery, so there is no problem there. However, many people require more than one battery for their camera. As an example, for my X-T3 camera, I currently have 5 batteries (all of them OEM): one in the body, two in the grip, and two spares. One was supplied with the camera, but the other four, still working well, were taken from my older X-T2. The point is, batteries can span camera generations. So even when the X-T2 went out of warranty, there was an advantage in purchasing OEM batteries as spares, because they later ended up being used in a new “under warranty” camera again (the X-T3).

INSURANCE

If you are a professional photographer, who has all of your photographic gear insured, you can effectively bypass the warranty issue, if your policy is comprehensive enough to cover battery failure, or battery instigated camera damage.

DELIBERATION

Statistically, most people will never have to make a warranty claim on their Fuji-X camera. Once the camera is out of warranty, this may not be an issue at all. You may be willing to take the risk of using a battery that, in the perhaps unlikely event that it damages your camera, could lead to you having to pay the repair (or replacement) costs. The probability of this not happening, is on your side. You may consider this an area where, although it’s nice to have the security, you are willing to save some money, by taking the chance that this issue does not ultimately eventuate.

[ 11 ] RELIABILITY

Reliability refers to a high level of confidence in a battery, both in terms of safety, and general operability. Battery reliability may be of critical importance to professional photographers, as well as other photographers who are working at a high level of camera expectation, or high rate of workflow. But it can also be relevant to any photographer who would like to have a trouble-free photographic experience. Unreliability can manifest as safety problems or service problems.

SAFETY RELIABILITY

Safety reliability is concerned with the battery’s ability to handle various types of accidental abuse. Assurance testing typically covers electrical, thermal, and mechanical types of abuse.

When subjected to these types of abuse, the battery should have a high level of resistance to combustion or explosion, or if the battery does combust/explode, the effect should be relatively contained (ie, not releasing flaming particles, or high velocity projectile fragments).

COMPLIANCE

Certification and conformity guarantee that the battery type has been tested up to appropriate standards. The Fujifilm OEM batteries comply with applicable standards for user replaceable batteries. The current battery displays 5 compliance symbols.

The battery may also be compliant with other standards, which do not mandate display of a symbol or marking (for example, transport of dangerous goods by air, under UN/DOT 38.3). Internally, the OEM battery shows compliance with relevant standards. For instance, the protection circuit board states compliance with UL 94V-0 Flammability Test, as well as carrying the UL Recognized Component mark (“backward R” U).

3rd party batteries frequently carry only the CE marking (which can be self-assessed), or no compliance markings at all.

FAKE CERTIFICATION OR CONFORMITY

Sometimes the certification or conformity markings (particularly the CE mark), of 3rd Party batteries are fake. An un-branded battery could not achieve proper CE conformity, because CE compliance must always be traceable, and someone must ultimately be accountable. Traceability facilitates market surveillance by the regulating authority, and makes the identification required for enforced withdrawals and recalls, possible. For CE conformity, the manufacturer needs to hold documentation, including a Declaration of Conformity (DoC), as well as a Technical File, which is a dossier fully documenting the evidence relating to the product’s compliance with the applicable safety standards. Obviously, such documentation (even if it does exist), is not open to scrutiny by the regulating authority, if the manufacturer is anonymous, or cannot be contacted or located. The product is also required to bear a batch, type, serial, or model number, for identification. The following battery lacks the basic features required for traceability. (In this case, it doesn’t even state the country of origin).

Other batteries give away their sham compliance by using an incorrect form of the CE mark. The true CE mark has a significant space between the two letters, due to the overlap of the two “construction” circles, underlying the design:

However, on the following 3rd Party battery, the spacing is reduced, and the middle bar of the E letter, is longer than it should be.

This look-alike symbol is sometimes referred to as the “China Export” mark. In terms of indicating conformity to safety standards, it has no real meaning.

SERVICE RELIABILITY

Battery reliability is not only concerned with safety, but also with the ability to complete the task at hand, without undue delays (such as unscheduled battery changes), erratic equipment behaviour, or data losses. Service problems can be: low shot count, “flat-without-warning”, high self discharge, short lifetime, and irrecoverable sudden battery failure. Battery failure (including full depletion without sufficient warning), can result in missing a key shot, or sudden stopping of a video sequence without the proper termination and shut-down procedure, resulting in possible data corruption, or even complete loss of the video file. Furthermore, there may be unforeseen events, which will push the camera and battery to the limits of endurance, and we would like to have confidence that the battery can handle these situations.

RELIABILITY OF THE PHOTOGRAPHER

For some professional photographers, it may be the case that use of OEM batteries is effectively mandatory. For instance, the risk of batteries failing during a shoot with no possibility of re-shoots or second chances (the ceremony part of a wedding shoot, or fast paced sporting events photography), could make the selection of battery type virtually non-discretionary. Your clients have a reasonable expectation that you have exercised due diligence in ensuring that their photographic brief can be fulfilled. Missing a key shot, because a battery, which was chosen on the basis of its lower cost, failed without warning, falls below the best standards of professionalism. If you happen to live in an ultra-litigious society, the fact of having used your equipment according to the directions of the camera’s manufacturer (including, using the specified battery), may form an important part of your defense, in case of a law suit brought against you, over a photographic brief marred by misadventure, either through failure to capture non-repeatable moments and events, or through accident or injury due to battery initiated fire or explosion. For professional photography, a higher price paid for OEM batteries might just be considered one of the costs of running the business.

TENDERING FOR CONTRACTS

Some professional photographers have experienced that when tendering for the contract of a video or photographic project from a government department, or a major corporate entity, contractual expectations for the tender may include submitting copies of recently developed risk assessments that are relevant to the tender, as well as evidence that equipment is maintained in accordance with manufacturer/legislative requirements. Strictly speaking, equipment needing to meet compliance with safety standards, would also include user replaceable lithium-ion batteries, and it may be that only the OEM battery is able to meet this requirement.

DELIBERATION

When exploring the critique of reliability, there are issues that are very significant for professional and highly specialised amateur photographers, that might not hold the same significance for the casual, recreational photographer. If we think of confidence in our equipment as, “having a good feeling that something bad won’t happen”, we have to recognise that the “something bad” has a different significance for the high-level pro (where a botched brief or battery-caused injury, could mean lawsuits, loss of reputation, or even bankruptcy), and for the specialist amateur (where it could mean the failure of a long planned and expensive project or expedition), compared to what it means to the casual photographer (where a missed shot may only be a transitory annoyance, and simply written off as bad luck). How important this issue is to you, only you can decide. Once again, you might ask, is the benefit of a high level confidence in equipment reliability, worth the extra battery cost?

[ 12 ] ULTIMATE VALUE

When I say “ultimate value”, what I mean, expressed in a few more words, is “Ultimately, it all comes down to the amount of user relevant Value (not necessarily monetary) delivered by the battery”. At the very beginning, we looked at battery price, and the differences between OEM and 3rd Party batteries were stark. In order to justify the higher cost, the OEM battery had better deliver a lot of benefits to the battery user.

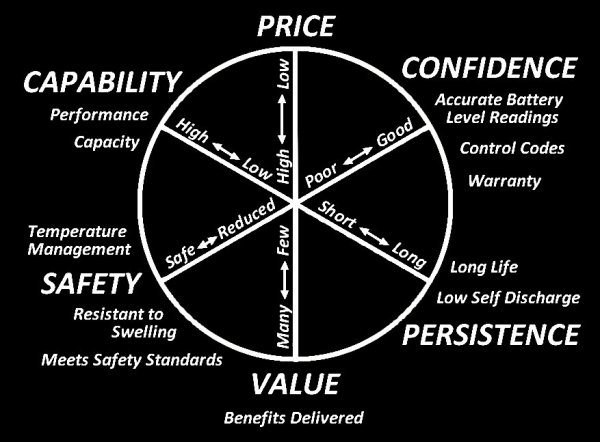

This is how I have chosen to present summaries for various battery types, in a very visual way, in order to assist “getting your head around” a very complex analysis. Your methods and conclusions may differ considerably. For a final analysis, I have brought together all of the criteria in a single chart, and further grouped the criteria into the categories of PRICE & VALUE, CAPABILITY & PERSISTENCE, and SAFETY & CONFIDENCE. This represents the personal way that I chose, to compile information about different batteries, for the purpose of producing an overview. You may have a method that suits your needs and preferences better. Please note that the selected criteria are by no means comprehensive, and the individual battery user may be in circumstances where other criteria (for instance, cold climate battery performance), may also be very important.

For the PRICE critique, a lower price scores higher, and its line has the related critique of VALUE at the other end. They are the two poles of the consideration: “How much does it cost, but also, how much do I get, for what I pay?” (For our purposes, the VALUE critique has simply been based on an aggregate of the capability, persistence, safety, and confidence scores).

Another line joins the related critiques of CAPABILITY and PERSISTENCE. Capability simply means the ability of the battery to power the camera, for an acceptable period of time, or for an acceptable number of shots. It means the battery has the capacity required by the photographer, and can deliver the performance required by the camera. Persistence means that the capability that we experience now, is able to be sustained into the future, both short term (low self discharge), and long term (long battery service life).

The third line joins SAFETY and CONFIDENCE. Safety should be relatively self-explanatory. But as well as its practical implications, working within a safe system also affects how we feel, while we work. Together with the “confidence” given by using a battery which is specified for the system, (feelings of) Safety and Confidence, operate in the “affective domain”. They can allow us to work with a positive and self assured attitude, rather than from a position of underlying apprehension of possible adversity. (For example “I would like to charge this battery in-camera, but I’m afraid that it might swell and get stuck”). In extreme cases, it could make the difference between photography being a fulfilling endeavour, or a stressful task.

This circular arrangement of the criteria will form the basis for a type of graph, variously known as a spider(-web) graph, or as a radar graph. The use of this graphic display is only intended as a tool for exploring the multivariate nature of battery choice, and is not intended as the graphic proof of a universal best choice battery. First, let’s look at:

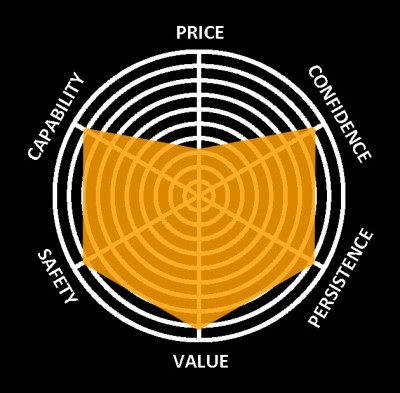

THE PERFECT BATTERY

This battery (which unfortunately does not exist in reality) achieves top scores on all measures, and cannot be surpassed. It is presented here, simply as an ideal to aspire to.

Apart from its perfect scores, the battery’s graphic profile is characterised by a “roundness”, showing that the battery addresses all relevant areas of critique, rather than concentrating on some and neglecting others. In terms of a graphic profile, this is the type of result that we would like to achieve.

THE FUJIFILM OEM BATTERY

This battery scores very well on all areas of critique, apart from price. Note that it never achieves full possible scores, in recognition that, in reality, there is always room for further development and improvement.

This would be a very well rounded battery, if not for the high (low scoring) price. The high price is testimony that research and development, materials selection, quality management, and achieving safety accreditations, all come at a monetary cost. You pay a lot, but you do get a lot for it. The question is whether some of those benefits (which you have paid for) are superfluous to you personal photographic needs (for instance, warranty implications, and accurate battery level display). It could be claimed that the price is out of proportion to the value, and this is reflected in the distortion of the shaded area of the chart, deviating from the roundness of the “perfect battery”. What do you think?

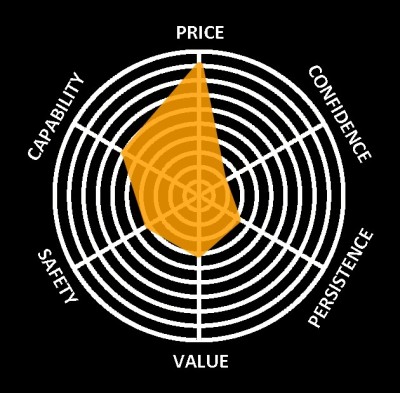

TOP-TIER 3rd PARTY BATTERY

These batteries are in the highest price-group of the 3rd Party batteries, and are generally highly respected. It is rare to hear bad reports about them. (Note that this group excludes those batteries that have a reputation for swelling, or an overstated capacity).

Safety has been marked down because the battery’s lack of thermistor is a compromising factor whenever the battery is charged in a Fuji charger, or charged in-camera. The capacity and persistence, which are the most obvious day-to-day criteria for battery worth, are good. For the price, we get a well rounded battery, and a good solid performer.

LOW COST 3rd PARTY BATTERY

These batteries deliver decent short term operability, at a very competitive price. However, over a longer time frame, their deficiencies begin to show. (Note that a lower capability score may simply indicate smaller internal cells, rather than being a reflection on the cell quality).

Over time, high self discharge, swelling, high cycle fade, and ultimately, short service life may become apparent. The low price is achieved partly through cutting production costs, which is seen along the SAFETY-CONFIDENCE line. Safety can be compromised by, for example, using soldering for terminal connections, rather than welding, and by using adhesive tape as an insulating cell-separator, rather than the specially designed cell-separator of the OEM battery. The graphic profile of this battery type is unbalanced, and very “un-rounded”. And yet, for some photographers, this battery suits their photographic needs, without incurring the extra costs of “benefits” that may produce little “real” difference for them. If you have a few of these batteries in your bag, then if one fails or misbehaves, just swap in one of the other back-up batteries. This is a practical type of reliability, achieved at a low cost.

DELIBERATION

I have tried, throughout this exploration of battery issues, to present mainly evidence based information, and avoid too much conjectural discussion. Yet, I am very aware that my analysis of a battery type’s worth, may differ from that of another experienced photographer, and I respect the value of the differing viewpoints. I hope that I have given sufficient technical material for the reader to arrive at their own informed judgement about which battery type (OEM or 3rd Party) represents the best choice for their own personal photographic style and needs. There is no universally correct answer, but there is an individually appropriate one.

THE DECISION

That bell marks the end of the final round. You’ve watched the battle. You’ve witnessed the blows. Now it’s time to make YOUR decision. Will it be the Fujifilm Champ, or the 3rd Party Contender?

And the winner is . . .

Thanks for reading –

THE GREAT BATTERY BRAWL

[ Last updated: 25 July 2019 ]

If you would like to support me in continuing to produce high quality reference material, like this, please consider donating, maybe even the cost of a coffee.

Ciao!

All images © 2019 Dom Varney

Photographic images on this page are licensed under a

Photographic images on this page are licensed under a

Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

The CE marks on the OEMs look suspicious too. On the other hand I’d only buy a battery with a UL mark today.

https://ec.europa.eu/growth/single-market/ce-marking_en

From that site:

“Please note that a CE marking does not indicate that a product have been approved as safe by the EU or by another authority. It does not indicate the origin of a product either.”

So what’s the point with CE?

Hi Håkan. The CE markings on the Genuine Fujifilm batteries that I have, are all correct, however I have seen counterfeits where the marking does not conform. Unfortunately, the CE system is is based on self-assessment, and the application of the CE mark to a product is based on the “honour system”. The product is not declared safe by the EU authorities, but by the product manufacturer. Can we trust them? My main point was, if you see something that looks like the CE mark, it is still not necessarily a guarantee of safety. As to you’re remark “So what’s the point with CE?”, I think that is a very good question. But I would certainly say that if the battery (or its delivery packaging) does not allow identification of the manufacturer (or the importer / wholesale distributor), then the CE mark (even if the real one) is meaningless, since there is nobody who can be held accountable, or made to produce the evidence to back up their assertion of safety, by way of testing and quality management records. The UL mark does give more confidence (except when it’s on a counterfeit, of course). Thanks for reading my article.

So no actual measured data to confirm or refute manufacturer’s claims?