A SURVEY OF OPTIONS AND STRATEGIES

This comprehensive reference guide assembles information relevant to supplying power to the Fujifilm X-T3 camera, in an optimal way. The level of examination ranges from broad system overviews, to detailed analysis suitable for persons who are using the X-T3 professionally. Although this information is presented within the context of the X-T3 camera, much of it (particularly the information regarding NP-W126 type batteries) is also relevant to other Fuji X-series cameras. I hope that this can help you to get the most out of your Fujifilm camera. There is an important disclaimer at the end of this guide. Please read it before acting upon any information given here.

CONTENTS

A – OVERVIEW

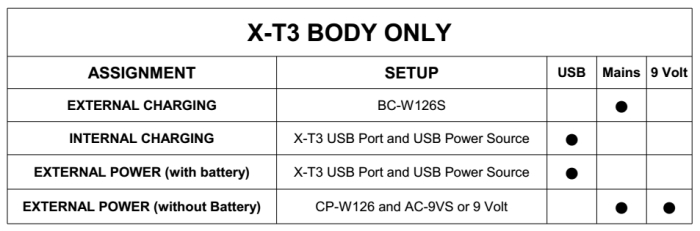

Body only power configuration options

Body and grip power configuration options

B – NP-W126S & NP-W126 BATTERIES

Specifications

Distinguishing between S and non-S

Performance differences

Determining the production date

C – NON-OEM BATTERIES

Genuine vs non-OEM batteries

Discharge characteristics

Identifying counterfeit batteries

D – VERTICAL GRIP

Battery discharge sequence

Battery deployment strategies

9 Volt DC input options

USB boost cable (5V step up to 9V)

E – LITHIUM-ION BATTERIES

State of health

State of charge

Calendar fade

Cycle fade

Detriments to service life

Charging

Charge rates

Charging times

Voltage limits for charge and discharge

Temperature limits

Voltage stabilisation

Measuring battery voltage

Battery contacts

Self-discharge

Storage

Determining the battery’s end of life

Li-ion fire hazard

F – POWER MANAGEMENT SETTINGS

View Mode setting

Auto Power Off setting

Power management menu

Boost mode

Performance mode differences

G – EXTERNAL CHARGERS

BC-W126S / BC-W126

Non-OEM chargers

Unexpected Interactions

Over-temperature protection

H – X-T3 USB PORT

Connection mode

Connector types

USB “Power Delivery”

Internal charging

External powering

USB power sources

Fujifilm AC-5VF power adapter

I – POWER BANKS

Advantages

Branded power banks

Port capabilities

Expected output current

Removable battery power banks

Expected efficiency

Multi-voltage power banks

Bicycle light battery boxes

Power banks recommended by Fujifilm

Capacity limits for air transport

J – DC COUPLER

Attachment

9 Volt supply options

D-Tap

Applications & examples

K – Alternative Power Supplies

Automotive power

Buck converters

How to use solar power

L – USB Power Meters

M – Disclaimer

SECTION – A

OVERVIEW

Currently (early 2019), the X-T3 camera boasts the most sophisticated and versatile power management system of any X-series camera to date. Many of its power management improvements were introduced with the X-T2 model. The significant differences between the X-T3’s power system, and the very similar power systems of the X-T2 and X-H1, are the X-T3’s adoption of the USB-C standard for USB connection, and the ability to achieve maximum performance without having to use the optional battery grip.

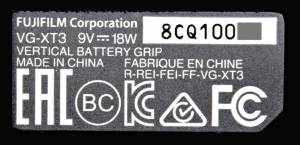

The electrical specifications of the X-T3, are found on the identification and compliance plates. The one belonging to the camera body, is at the back of the tilt LCD screen, and can be seen when the screen’s top is pulled outward, while the other plate is found on the top surface of the optional vertical grip. Both state that the camera is rated at 9 Volts up to a power of 18 Watts.

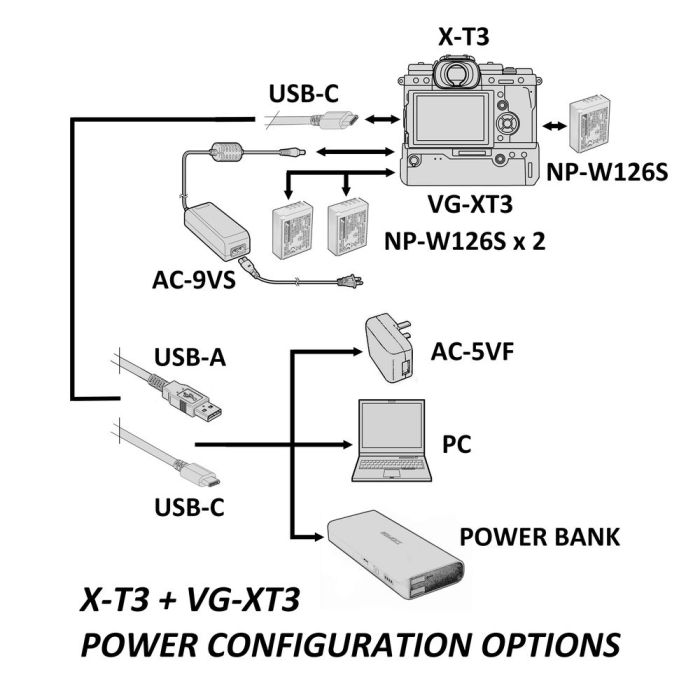

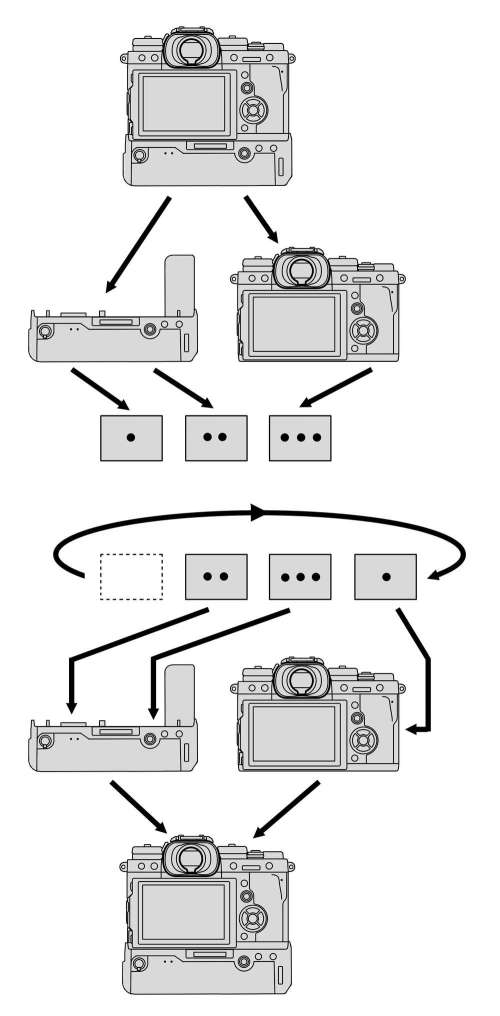

In terms of power options, use of the grip adds some, but at the same time, obstructs some others. For instance, while the grip is attached, there is no access to the camera body’s battery chamber. Because of this, there are two slightly different power configuration schemes for the X-T3, depending on whether or not the optional vertical grip is used.

When the optional VG-XT3 grip is used, it is possible to leave the grip attached quasi-permanently, since there is no need to access the body battery for external charging, (although, you still have the external charging option, if desired).

Section – B

NP-W126S & NP-W126 BATTERIES

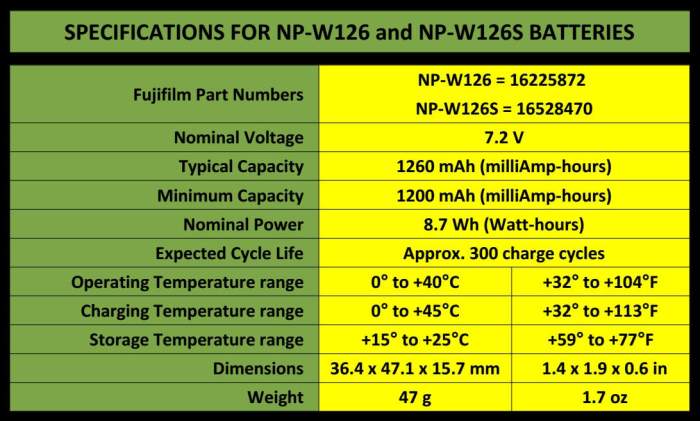

The NP-W126S is the specified battery for the X-T3 system (X-T3 body and optional VG-XT3 grip). Because some X-T3 owners might already have NP-W126 (non-S) batteries from an earlier camera, and they would like to use those batteries in the X-T3, the distinction between the two battery types can become an issue. The newer NP-W126S battery is a higher performance version of the NP-W126 battery, and was introduced to meet the needs of the X-T2 camera. These requirements on battery capability are extended further by the X-T3’s even higher performance specification. To the question “Can NP-W126 (non-S) batteries be used in the X-T3?”, the short answer is “Yes, but the camera may not be able to perform at its highest specification potential”. For some types of photography (for instance, Landscape photography, and Product photography) a reduction in “speed” performance, may simply not be an issue.

The NP-W126 and NP-W126S batteries are identical in terms of physical dimensions and power capacity, and may be considered interchangeable for lower paced situations where top performance is not required.

The specific internal difference between the two battery types is the lower internal resistance characteristics of the “S” version. Low resistance enables high current flow with minimal temperature rise. The readily identifiable visual indicator of battery type is the orange square on the end of regular NP-W126 batteries, and the orange circle (plus the orange insertion direction arrow) on the NP-W126S batteries.

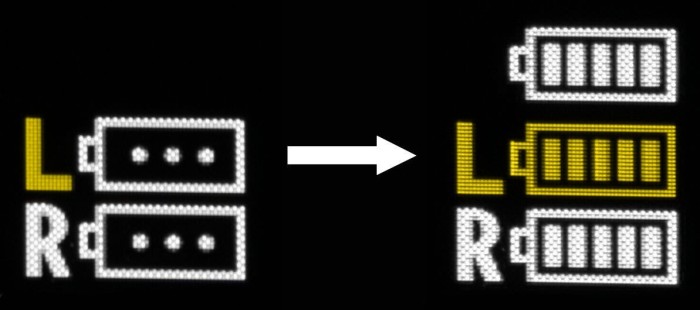

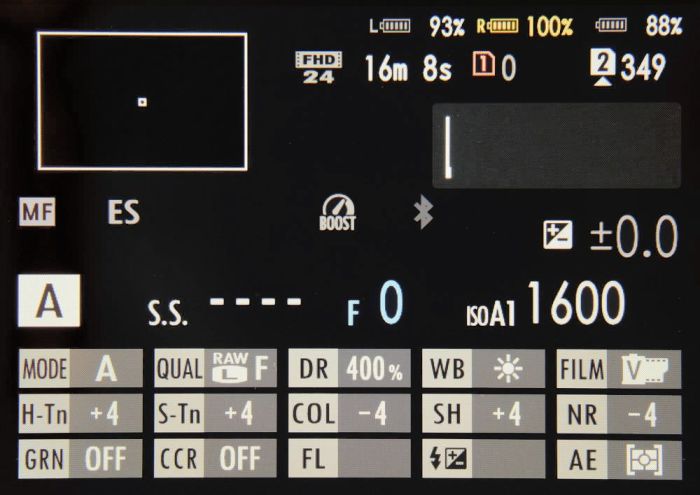

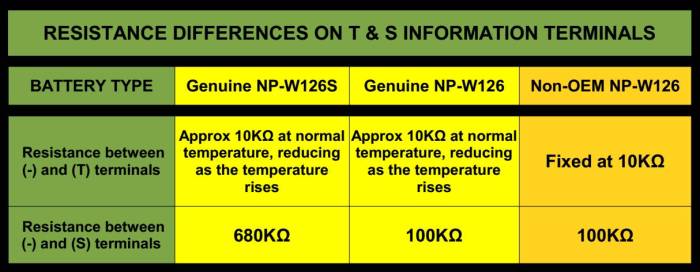

BATTERY TYPE DISCRIMINATION BY X-T3

When the X-T3 is powered up, any battery that is not an NP-W126S (this includes the NP-W126, and non-OEM batteries), is identified. The X-T3 determines the type by measuring for high resistance (about 680kΩ or higher) on the [S] contact of the battery, to indicate an “S” type battery. (If you tape over the [S] contact of a non-S type battery, effectively giving it infinite resistance, the X-T3 will mistakenly recognise that battery as an NP-W126S battery). If three batteries are loaded (1 in the body, 2 in the grip), at power up, the battery symbols for the grip batteries, display briefly with the “three dots” (meaning the battery’s state of charge is being assessed). At this stage, the “S” or “non-S” battery type has already been determined, and Left and Right grip battery indicators show in either white (for “S” type) or yellow (for “non-S” type battery).

Within one second, the display shows all three battery indicators, with their appropriate charge levels, and displayed in either white or yellow. Any yellow display (meaning a “non-S” battery is detected), will be accompanied by a message recommending the use of NP-W126S batteries.

Note that the message uses the advisory “Please use …” rather than the imperative “You must use …”. This, as well as the fact that the camera continues to work, indicates that the message is to be taken as an recommendation, rather than a directive.

PERFORMANCE DIFFERENCES

The performance differences between the regular and the type-S battery, are to do with sustained high power delivery over time, rather than with stored capacity. The type-S battery was intended to meet the increased endurance requirements of the previous X-T2 camera, when operating in scenarios such as high-rate continuous stills shooting, and long duration 4K video capture. Without the higher performance battery type, sustained high power usage could produce elevated battery temperature, an increase of the battery’s internal resistance, and a drop in output voltage, leading to possible camera “lock-up” events. In a lock-up event, the camera becomes unresponsive to all controls, including the on/off switch. Typically, the batteries must be removed and re-inserted before operation can be restored. The NP-W126S battery’s lower internal resistance characteristics were designed to address such issues. At the time of introduction (for the X-T2) Fujifilm stated that the improved battery could deliver three times longer duration of continuous shooting, even under 40 ℃ environmental conditions. However, for less demanding usage scenarios, the regular NP-W126 battery should perform satisfactorily, although with limitations to the X-T3’s boost mode.

PRODUCTION DATE

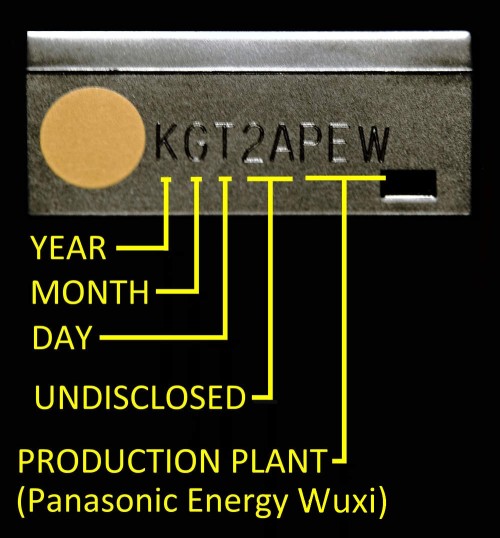

The battery’s performance potential declines over time, even if not being used. Therefore, in order to assess their service viability, it is useful to be able to determine the age of the NP-W126 class batteries, via their production date. This is recorded via an impressed alpha-numeric code on the end of the battery opposite to the electrical contacts end.

NP-W126 batteries having codes beginning with T, S, R, and P, had 5 characters. For codes beginning with N, and then on all NP-W126S batteries, the code is extended to 8 characters. (Please note that very early versions of the battery, prior to having the orange orientation patch, used a different production code system to the one described here). Of the 8 characters, the first three are the date code, the middle two (usually “1A” or “2A”), are undisclosed production information, and the last three are a manufacturing plant code. Note that Day of Month codes, don’t use alphabetic upper-case “I”, to avoid confusion with numeric character “1”, one. (However, this is not an issue for Year and Month codes, which don’t use numbers at all). For similar reasons, zero, “O” and “Q”, are not used. To the camera user, it is the first two characters (indicating year and month) that are of interest.

The production date information can be decoded by using the chart below. In the above illustration, the “KGT” date code can be decoded as “2018, July, 26”. Note that the year of production code proceeds in a reverse order. As a consequence, a letter closer to the beginning of the alphabet represent more recently produced battery. Since a Li-Ion battery’s prime operating condition only lasts about two years it is worthwhile remembering the year codes representing the last two years, since these represent the batteries that are currently within their prime. Batteries beyond the two year period may still be usable for casual photography, but for critical and high power demand usage, batteries within the recent two year production period, should be preferred.

At time of release, the X-T3 should have been supplied with a battery whose production code starts with K. As we get a few months into 2019, production codes starting with J should start showing up.

SECTION -C

NON-OEM BATTERIES

Non-OEM (Original Equipment Manufacturer) batteries are also known as third-party batteries. Batteries that are “nominally” equivalent to the NP-W126, but not genuine Fujifilm batteries, (and therefore, not manufactured by Panasonic Energy Wuxi), are readily available, and at prices significantly below the price of the genuine NP-W126S batteries. Although the nominal specifications may suggest the non-OEM battery as a viable alternative to the genuine battery, there can be significant performance, behavioural, and safety differences.

GENUINE Vs NON-OEM BATTERIES

Although more costly in the short term, genuine Fujifilm batteries offer the following advantages over non-OEM batteries:

Stated capacity is reliable. The genuine Fujifilm batteries are rated at a capacity at or close to the maximum that is attainable for the technology, and their nominal capacity matches their actual capacity. Third-party batteries claiming significantly higher capacities are generally overstated.

The genuine Fujifilm batteries can fully utilise the camera and charger’s power management system. This means that all four battery contacts, [+], [T], [S], and [-], are functional. On some non-OEM batteries, the [T] and [S] contacts are either set at a fixed value, or un-connected to any appropriate circuitry. This non-functionality of the [T] (temperature control) could have safety consequences.

The genuine Fujifilm battery’s designation as a high performance “S” type, is reliable. Non-Fuji batteries can make this claim, as a pretense, by simply labelling them as an “S” type, and changing the resistance value on the [S] contact from 100kΩ to 680kΩ, without any other internal changes to the “non-S” chemistry or construction. (The camera will report this fake as an NP-W126S battery).

Production date, and so the age of the genuine battery, can be established with certainty. This can be very important for long term power management and planning. Also, if you are able to inspect a battery, before purchase, you could avoid purchasing old stock (bearing in mind that, for distribution and and logistics reasons, we could expect even the “freshest” batteries to be several months past their production date).

There could be warranty implications. If the camera was damaged as a result of a battery defect, obviously the question of whether the battery was a genuine Fujifilm battery, or a non-OEM battery, would be crucial to the outcome of any warranty claim.

Capacity against voltage profile is as expected by the system, so the battery level indicator works as it was designed to.

Extensive information regarding differences between The Fujifilm battery and non-OEM alternatives, is given in The Great Battery Brawl.

DISCHARGE CHARACTERISTICS

The relationship between, battery voltage, remaining capacity, and expected time before power is depleted, is non-linear. The discharge curve for the genuine NP-W126S battery differs from that of other batteries. Unlike the fairly simple curve of the genuine batteries, the discharge curve of the third party batteries tends to be more complex, with multiple inflections. Since the camera’s battery monitoring system is calibrated against the discharge curve of the genuine NP-W126S battery, the camera will not read the current capacity of other batteries accurately (unless the battery happens to have exactly the same discharge profile as the genuine NP-W126S battery). Unfortunately, this renders the X-T3’s ability to give detailed percent-remaining capacity information for non-Fuji batteries, not very meaningful.

TESTING THE DISCHARGE CHARACTERISTICS

Genuine NP-W126S batteries, and representative non-OEM batteries, were tested in order to establish the discharge characteristics against the battery level indicator. Each battery was fully charged using the supplied BC-W126S charger. When fully charged, the battery was removed and allowed to rest for 90 minutes, so that the open-circuit voltage could stabilise. The voltage was measured and recorded, and the battery was inserted into the X-T3. 4K video shooting was initiated. As soon as the indicator dropped by one bar (an “indicator event”), the video was terminated. The battery was removed immediately, and its open-circuit voltage measured and recorded. The duration of the video recording was used as a measure of elapsed time. The camera and battery were allowed to rest for a 10 minute cooling time, before the battery was again inserted, and video shooting re-initiated, until the next battery indicator event. This process cycle was repeated until the eventual camera shutdown, due to depleted battery.

After testing, I differentiated the results into 3 groups, which I have arbitrarily called type 1 (the genuine Fujifilm batteries), type 2, and type 3. The results for batteries within each type group, have been averaged, in order to give a very generalised view of the discharge behaviour typical of that battery type. Please note that, because the testing placed the batteries under very high stress, the results could be considered as those of a worst case scenario. You may actually get better discharge behaviour than what these results indicate.

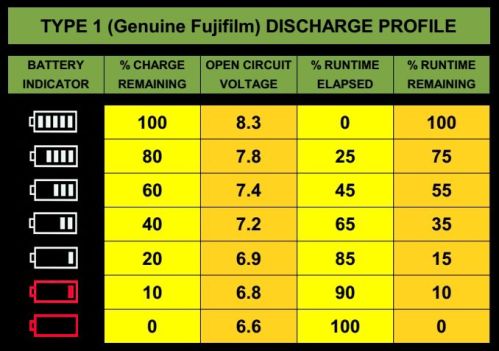

TYPE 1 – GENUINE FUJIFILM NP-W126S BATTERIES

Because the battery level monitoring system of the X-T3 is calibrated against the genuine Fujifilm battery, the indicator symbols when using that battery, are informative, reliable, and accurate. Note that the remaining charge percentage and the remaining runtime percentage, don’t exactly match, because their relationship is non-linear.

Perhaps most importantly, the indicator gives adequate warning before system shutdown due to battery depletion.

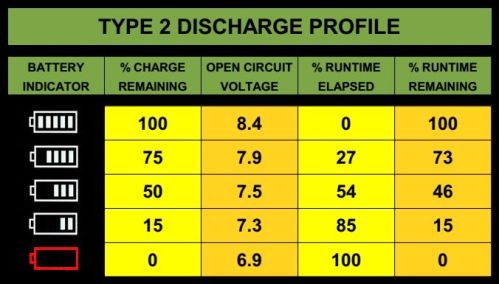

TYPE 2 – TYPICAL HIGH CAPACITY NON-OEM BATTERIES

These batteries are well regarded by some people, because they deliver similar capacity to the genuine Fujifilm batteries, but at only a fraction of the price. However, they have the least conformity to the X-T3’s calibration curve. Their actual degree of discharge is always higher than what is shown by the battery indicator, and this discrepancy increases as the battery discharge progresses. By the time the indicator displays 2 bars, the battery is almost fully discharged, and low-battery shutdown follows quickly, with little or no warning.

Notice that this type of battery may not display the one bar battery symbol, but goes straight from two bars to empty.

TYPE 3 – TYPICAL LOWER CAPACITY NON-OEM BATTERIES

These batteries are low cost, and typically have capacities in the range of 1000 – 675mAh, (which may be overstated on their label, by up to 45%). At the beginning of discharge, the actual charge remaining is slightly higher than indicated, then at about midway (3 bars) the display is fairly accurate, and finally, in the low number of bars, the actual charge remaining, is less than indicated. Due to the fact that the battery has a lower maximum capacity to begin with, full depletion is reached very quickly, when the indicator is in the low number of bars. By the time the indicator displays 1 bar, the battery is almost fully discharged. If the low-battery warning is given, shutdown might follow within a couple of seconds.

Because of their lower capacity, these batteries tend to overheat when charging, (the charging current, which has been chosen for a 1260mAh battery, is too high for the lower capacity), and so these batteries often become swollen if the charger does not implement over-temperature protection.

IDENTIFYING COUNTERFEIT BATTERIES

Simply being a non-OEM battery, does not make a battery counterfeit. To be counterfeit, there must be an attempt to deceitfully pass (via fake packaging and labeling) the battery as a genuine Fujifilm battery. Suspicions regarding the battery’s authenticity generally arise from, low purchase cost, poor performance, or the experience of the battery having a tight fit in the battery chamber. The following anomalies, (a more comprehensive list can be found in NP-W126S COUNTERFEITS: A Visual Guide to Spotting the Fakes), can help distinguish counterfeit batteries from the genuine (manufactured for Fujifilm by Panasonic) batteries:

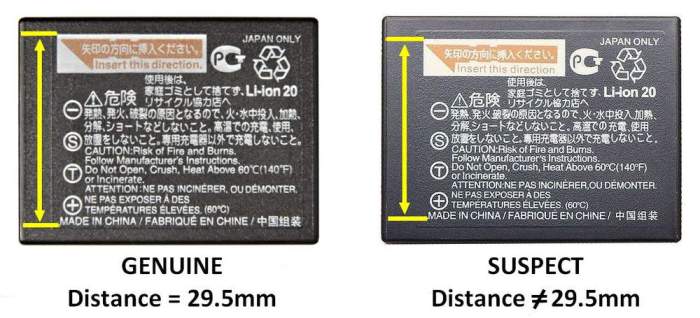

Check the dimensions of the printed area of the suspect battery against those of a known genuine battery. When the printed information on the genuine battery was scanned for the purpose of reproduction on the counterfeit, some re-scaling may have taken place, leading to a slight difference in the bounding dimensions of the information printed on the battery.

Weigh the battery, with accurate electronic scales. Genuine batteries weigh very close to 47g / 1.7oz. Non-OEM batteries can be anywhere in a range of about 39-50g.

Check the flatness of the printed sides of the battery. Genuine Fujifilm batteries have a concavity to the sides, which can be seen by placing a straight-edge against them, and viewing against a bright background. The concavity can even be felt by rubbing over the surface with your finger. The genuine batteries will not have flat, or convex (bulging in the middle) sides.

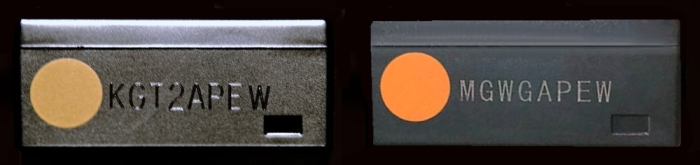

Check the production code information on the end of the battery. Possible anomalies include: non-existent code, non-conforming code, or code that is ink-printed (rather than heat-impressed). In the following photograph, the battery with code starting KGT, is genuine, while the one with code starting MGW (printed in white ink), is a counterfeit.

A counterfeit battery may not show all of these anomalies, but it is likely to show several of them.

Section – D

VERTICAL GRIP

The Fujifilm VG-XT3 vertical grip (from this point on, simply referred to as the “grip”) is an option designed to facilitate use of the camera in “tall” or “portrait” orientation, as well as providing further power options to those given by the body alone.

The grip can be used with either two or one batteries, or even without batteries, (if you want the “tall” format ergonomics, but don’t need the weight of extra batteries). It can also be used, either attached to, or separated from the camera, as a dual battery charger. Charging takes approximately 120 minutes (when charging two batteries simultaneously) . Note that the Owner’s Manual (p. 247), states: “Use only NP-W126S batteries”.

BATTERY DISCHARGE SEQUENCE

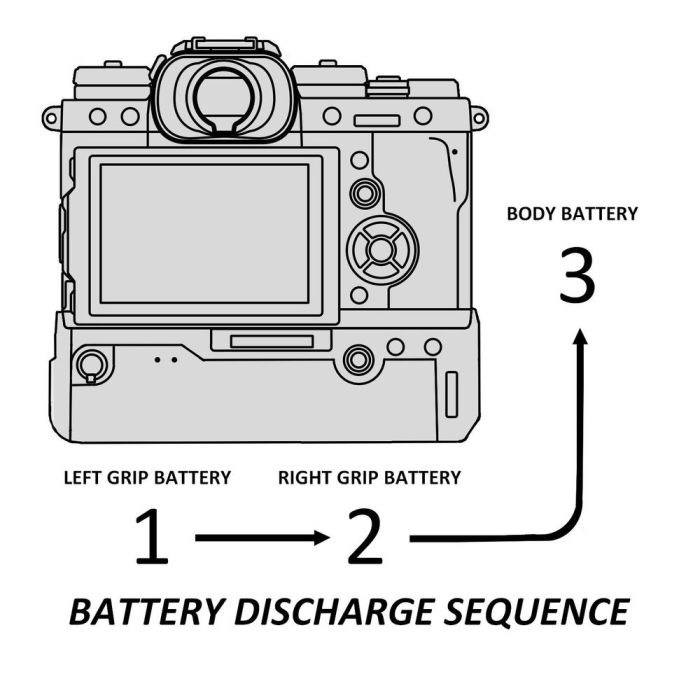

For battery management reasons, you may sometimes want to prioritise a battery for discharge. As a general rule, the batteries are discharged starting from the left, and working towards the right. For light duty power demand, the three batteries are discharged in the following sequence: First, the left-hand grip battery, next, the right-hand grip battery, and finally, the body battery.

For sustained high power usage (continuous shooting, and high power demand video), the body battery supplements the power supplied by the currently designated-for-discharge grip battery, with the body battery being discharged at a lesser rate than the grip battery. The discharge sequence in this case is: First, the left-hand grip battery plus body battery, next, the right-hand grip battery plus body battery, and finally, the body battery.

BATTERY DEPLOYMENT STRATEGIES

You may be using a mix of batteries that differ in both type and age. The arrangement of the batteries in order of far grip battery to body battery, may have implications for your workflow. Also, certain battery arrangements could, if used for a long period of time, result in some batteries being under-utilised, and others being over-utilsed. For the sake of both efficiency and economy, it may be worthwhile putting in place an appropriate battery deployment strategy.

MIX OF “S” AND “NON-S” BATTERIES

If using a mix of non-S and type-S batteries, it is recommended to place an “S” battery in the camera body. When the batteries are assigned this way, the camera can always have access to the highest performance type battery, even if the other two batteries have become discharged.

EXPLOITATION STRATEGY

The exploitation strategy pushes your best (youngest) battery to the front of the discharge queue. This gives maximum usage value in terms of total lifetime shots against the purchase price of the battery. An advantage is that batteries are never under-utilised, and the strategy is very cost efficient. A disadvantage is that you can start with plenty of power at the beginning of a session, but the second and third batteries discharge more quickly than the first, so you may get less warning when all batteries having become depleted. It’s a good strategy if your shoot sessions are typically short.

CONTINGENCY STRATEGY (CONSERVATION STRATEGY)

The contingency strategy pushes your best (youngest) battery to the rear of the discharge queue. It considers the grip batteries as the working batteries, and the body battery as a back-up or contingency battery. Applying this strategy, when both of the grip batteries have become discharged, you should plan to replace or recharge them immediately, rather than continuing to photograph and running down the body battery. This strategy helps to ensure that you always have reserve power, so that you don’t lose power at some critical point in shooting, and also avoids having to regularly remove the grip to change a flat body battery, during the shoot. In this strategy, your “best” battery, is being kept in reserve, to ensure that you are able to cope with any unforeseen circumstances. The down side of this strategy is that the “contingency battery” may be under utilized during its typical two years of life expectation. Of course, whenever a new battery is purchased, it takes the place of the reserve battery, and the old reserve battery can be places in the grip as a working battery. This usage strategy is good for long shooting sessions, where you typically have to do battery replacements during the shoot.

ROTATION STRATEGY

This strategy distributes the usage over each of the batteries, so that none of them become overused or underused. This strategy is particularly recommended if you typically don’t remove your batteries from the camera and grip (that is, you use internal charging methods). The position of each battery in the system is rotated on a regular interval basis. An ideal interval would be a monthly cycle.

In a (say) five battery system (one in the body, two in the grip, and two spares), the two additional batteries can also be inserted into the rotation sequence, but you may have to do some record keeping, so that you can determine the correct sequence at rotation time. Be aware that, if all of the batteries were of approximately the same age, at the beginning of this strategy, they will all start to show signs of aging (decreased exposure counts) at approximately the same time (about two years on). So this strategy works better if a new battery is purchased at regular intervals (say, at the end of the first year, and then every six months), which should not be an unreasonable demand if working professionally.

9V DC INPUT

A DC power input socket (EIAJ-03) is under the rubber seal on the left-hand side of the grip.

This socket is intended for the AC-9VS power adapter, that is supplied with the grip, and which can be used for both charging and supplying operational power, although not simultaneously. When the camera is turned off, the 9 Volt input will supply power for charging the grip batteries (but not the body battery). If the camera is turned on, then the 9 Volt input will supply power for camera operation.

The camera can operate without batteries if powered via the 9 Volt input, although to attain the camera’s highest performance, it may be necessary for the DC input to be supplemented by some battery power, (at least one partially charged battery).

DC INPUT PLUGS

There is the possibility of supplying 9V power using power sources other than the AC-9VS. However, for operation without batteries, the voltage supplied via the DC socket, should not go below about 8.75 Volts; otherwise the display will flash the low power symbol (red battery with no bars), and the camera will auto power-off. The grip’s DC input is a standard socket complying with the relevant Japanese standards, and accepts an EIAJ-03 plug.

This socket is not compatible with plugs adhering to the other common standard, which is IEC 60130-10, although one of that standard’s plugs will loosely fit the socket in a way that is neither secure nor reliable. If using a 9 Volt power source other than the AC-9VS power adapter, it may be necessary to make up the appropriate cable (soldering and polarity discrimination skills required), in which case, the proper camera-end plug can be identified from the following table:

If searching online, the plug will typically be identified as a 4.8 x 1.7 mm plug. The “signature” yellow plastic tip, while common on the EIAJ-03 plug, is not unique to it, nor is it required by the standards. (In fact, Fujifilm uses a black plastic tip). However, the yellow tip can be a useful indicator of possible-candidates when searching for an appropriate plug.

USB BOOST CABLE

The USB boost cable (5V to 9V step up), is a further option for supplying power via the grip’s DC input socket. It is recommended that you only use one battery in the grip when using the boost cable (the reason is given further down). The USB boost cable can be plugged into any suitable USB power source, such as a power bank, a personal computer, or a USB wall convertor. Typically, you would need a 5.5 x 2.1mm female to 4.8 x 1.7mm male adapter or conversion cable, in order to connect the converter to the VG-XT3’s DC input socket.

The standard USB 5 Volts is up-converted to 9 Volts, with however, a corresponding reduction in the supplied current. For example, if the power bank can supply 5 Volts at a maximum of 2 Amps (5V x 2A = 10 Watts), then the boost cable won’t be able to supply more than about 1.11 Amps of current (9V x 1.11A = 10 Watts) after the voltage conversion. The actual current will be less than this, if we take conversion losses into account, but for practical purposes, we can consider that the current is approximately halved, so 1 Amp. For comparison, the AC-9VS power adapter can supply 9 Volts at 2 Amps (18 Watts). The boost cable delivers sufficient power to supply the camera for moderate power demand stills shooting, and for grip charging of one battery.

If grip battery charging of two batteries is attempted, the boost cable will demand more than the power bank’s (typical) 2 Amp total current limit, and the boost cable itself, will be pushed outside its operating limits. This will cause the boost function to fail, with inability to achieve the required 9 Volt supply. To reset the system, the boost cable has to be disconnected, and the reconnected, with the appropriate reduction in current demand. To avoid this problem, it is recommended that one of the batteries be removed from the grip, so that if the grip goes into charging mode, the limits of the boost cable are not exceeded. Unlike power delivered via the camera body’s USB socket, input through the grip’s DC socket can power the camera, even without any batteries inserted (camera or grip). Again however, keep in mind the boost cable’s limit of about 10 Watts of power, whereas for highest level of performance, more than 18 Watts (AC-9VS power adapter plus at least one battery) may be required.

Section – E

LITHIUM-ION BATTERIES

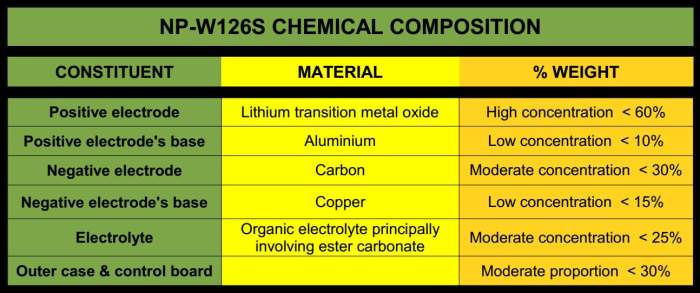

The NP-W126S and NP-W126 batteries are constructed of two series-connected metal-can type prismatic lithium-ion cells, together with a built-in power management board, all of which is sealed in a polycarbonate case.

(In what follows, “lithium-ion” will usually be abbreviated to “Li-ion”). The exact chemical composition of the NP-W126S battery is proprietary information. However, some information can be gleaned from Safety Data Sheets, lodged for the purpose of compliance with international transport regulations.

The exact transition metal component of the positive electrode is not openly specified, but the candidate metals are: Co, Mn, Ni, and Al. In what follows, specific information that was available from Fujifilm and from Panasonic Energy in Wuxi (the battery’s normal manufacturer), is supplemented by information which applies to Li-ion batteries in general.

BE CAREFUL – NOT FANATICAL

The following information is intended to assist you rather than burden you. In real life practice, it is not possible to follow all of the best advice, all of the time. We should differentiate between occasional sub-optimal battery treatment, and habitual misuse. Since the battery has a limited life regardless of how carefully it is treated, there is little point in becoming obsessive-compulsive in regard to maximising battery life.

BATTERY STATES AND PERCENTAGES

There are two commonly quoted Li-ion battery states that may both be expressed as percentages. One is the battery’s State of Health (SoH), and the other is the battery’s State of Charge (SoC).

STATE OF HEALTH

State of Health is a ratio of the battery’s present capacity for storing energy, compared to the battery’s original capacity at the time of manufacture. SoH speaks to whether the battery is, viable for continued usage, or approaching the state of being considered a dead battery. The expression of SoH as a percentage is more conceptual than practical, because the user usually doesn’t have an instrument to directly measure the SoH, and it is typically inferred from the battery’s age and performance. By definition, the battery’s capacity when new will be 100%, but this percentage will decline with time and usage. We are typically interested in the range from 100% to 80%, because when the SoH reaches a conceptual 80%, there is a noticeable fall-off in battery performance. For the photographer, this fall-off generally manifests as a reduced number of shots per charge, and around 80% is a typical point at which we might consider withdrawing the battery from primary service, and replacing it.

STATE OF CHARGE

State of charge is a ratio of the battery’s present actual deliverable energy, compared to its present potential for holding deliverable energy (which is, of course, largely dependent on the battery’s SoH). State of Charge is what is displayed by the camera’s battery level indicators. When fully charged, the SoC is 100%, but when “flat”, the SoC would be reported as 0%. Keep in mind that 0% is relative, and does not mean absolutely zero energy. Li-ion batteries cannot tolerate being at very reduced voltages, and so a certain amount of electrical potential must always be reserved, to keep the battery in a safe electro-chemical state. This reserve is handled automatically by the camera’s power management system, and generally need not be a concern of the user. But, as a consequence of this reserve, not all of the battery’s electrical energy is available for use by the camera.

To summarise, a flat battery will have a low State of Charge (say 0%) and the remedy is to re-charge it, while a dead (or dying) battery will have a low State of Health (say 80%) and the remedy is to replace it.

BATTERY LIFE EXPECTATION

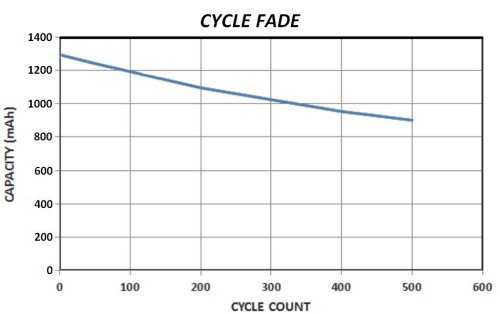

As a general rule, Li-ion batteries do not suddenly “die”, but rather, they show a gradual decline in capability. Within the context of that decline, we can broadly identify a transitional phase when the battery’s performance goes from meeting expectations to failing to meet expectations. We can consider the service period up to the “failure to meet expectations” point, the life of the battery. The Li-ion battery’s life inevitably declines due to two processes known as calendar fade and cycle fade.

CALENDAR FADE

Calendar fade refers to a time related decline in capacity, which is independent of charge-discharge cycling, and which even affects batteries that are not being used. (Note that calendar fade is also accelerated by high temperatures, so it is beneficial for batteries to be kept cool). The commonly accepted rule of thumb is that, after 2 years, a Li-ion battery can only hold 80% of its original capacity. In general, at 80% capacity, although the battery is still usable, it is noticeably under-performing.

CYCLE FADE

Cycle fade refers to an in-service related decline in battery capacity due to repeated charge-discharge cycling. Fujifilm states an expectancy of 300 charge-discharge cycles for the NP-W126 class batteries (Owner’s Manual, p. 274). Again, capacity falling to 80% is the criteria for determining expected cycle numbers.

BALANCED USAGE

If we try to balance these fade processes by aiming for the calendar fade endpoint and the cycle fade endpoint to coincide, (300 cycles distributed over a period of 24 months), we are looking at roughly 3 charge-discharge cycles per week, for a single battery. We can consider this as a hypothetical standard-usage-density for the purpose of determining whether the battery is being over or under utilised.

NEW BATTERIES

The Owner’s Manual (p. 28) states: “The battery is not charged at shipment.” New batteries are delivered with approximately 30% SoC. This is partly to extend service life by keeping the battery in a preferred storage state until the user has taken delivery of the battery, and partly due to transport regulations, (specifically, transportation by cargo aircraft under UN3480, Class 9 Dangerous Goods category, with state of charge not exceeding 30%), since Li-ion batteries are safer (less likely to enter a thermal-runaway condition if subjected to elevated temperatures) at a lower SoC. The new battery may have to be charge and discharge cycled about three times before it gives normal charge and discharge behaviour. This is because Coulombic efficiency (the ratio of the total charge extracted from the battery to the total charge put into the battery over a full cycle), improves with cycling. Previous to the battery being cycled, its Coulombic efficiency may have been between high-80’s to mid-90’s percent. After a small number of cycles, it can approach 99% or higher. Some batteries have already been cycled by the manufacturer, before delivery.

DETRIMENTS TO SERVICE LIFE

The following situations or conditions should be avoided to ensure that the Li-ion battery is not un-necessarily stressed.

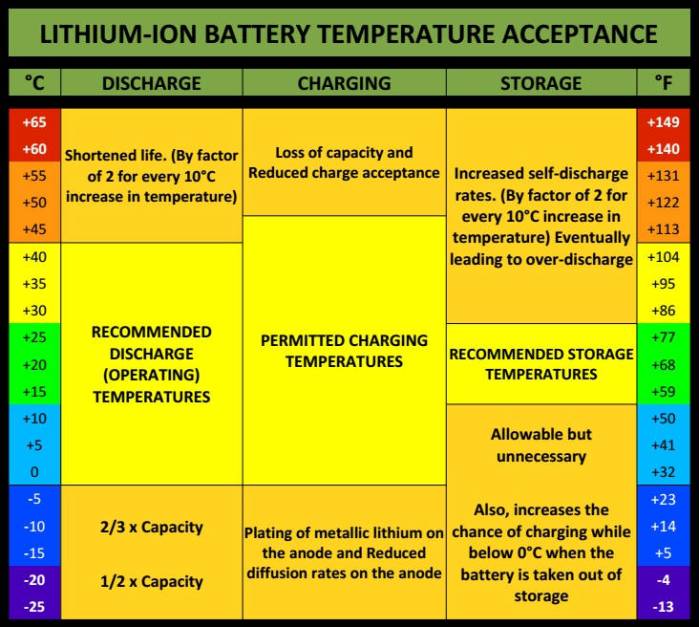

• Avoid high temperatures (should not be subjected to > +45°C or +113°F)

• Avoid ultra-fast charging (Rate of charge greater than 1C)

• Absolutely avoid charging at temperatures below 0°C.

CHARGING

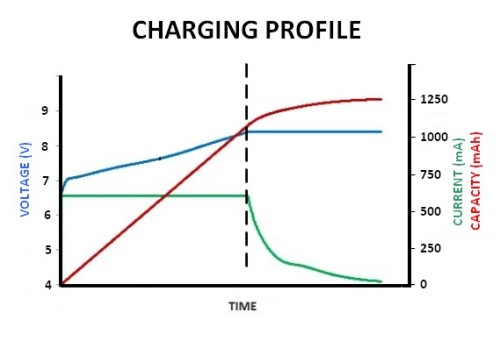

Li-ion batteries are charged according to the constant voltage (CV) / constant current (CC) method. The charge process has two main phases. In the first phase, the current is constant, at a value determined by the selected C-rate, the voltage steadily climbs, and the increase in charge, over time, is linear and rapid. In the second phase (saturation phase), when the maximum charge voltage (8.4 Volts) has been reached, the voltage becomes constant, the current drops rapidly, and the increase in charge, over time, becomes non-linear, and slower. If charging is being monitored, the rapid drop in current is a good indicator of the position in the charge process. Charging terminates when the current drops below a threshold (0.1C is typical).

CHARGE RATES

Battery charging times are mainly dependent on ambient temperature and charging rate. Charging rate, or C-rate, is the expression of charging current normalized against battery capacity. For example, when charging with a rate of 1C, a 1200mAh capacity battery would be charged at a current of 1200mA, and would be fully charged in 1 hour (theoretically). Note however, that a rate of 1C is considered to be higher than optimal, and the recommended fast charge rate is 0.7C. Because very high rates of charging are detrimental to the long-term condition of the battery, high-rate charging is usually terminated earlier in order to avoid detrimental effects. As a consequence, the available capacity changes per different C-rates, with the higher C-rates typically producing slightly less available capacity.

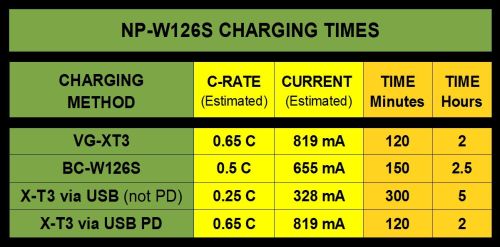

CHARGING TIMES

The X-T3’s different charging methods use different charge rates, and as a result, have different charging times. Of the available charging methods, charging via the grip uses the highest rate, and can charge two batteries simultaneously. Charging via the camera body’s USB port (if not using USB PD or “Power Delivery”) has the lowest charge rate and, although the slowest method, is probably the best for the battery, both in terms of available capacity, and long-term battery health.

If using an external power monitor, be careful not to confuse input current with charging current. You can avoid this problem by working in Watts (current x voltage). For a USB input, the voltage will be 5 Volts (even for USB PD). For charging, the voltage will be 8.4 Volts. USB PD is explained more thoroughly in Section H, about the X-T3 USB Port.

PARTIAL CYCLING

Li-ion batteries do not have any significant memory effect, so there is no absolute requirement for Li-ion batteries to be fully-cycled on a regular basis. They can be partially cycled, but be aware that the various part-cycle patterns can differ in their beneficial or detrimental contribution to long term battery health. Ironically, (and different from many other battery types), the “fully charged” state is more stressful to the Li-ion battery than lower states of charge, and leaves the battery more susceptible to electrolyte oxidation, which is cumulatively detrimental to its life, each time the fully-charged state occurs. Therefore, full cycling (fully charge, then fully discharge), is preferable to “top-up-to-full” partial cycling, because, in the long run, it results in fewer instances of being “fully charged”.

If you know that a shoot will only require a small number of shots, (perhaps a couple of dozen), then there is no problem with giving a discharged battery a shorter charge , say 40 to 60% of full capacity. Routinely charging the battery to slightly less than full capacity (90% would be ideal), has a beneficial effect on battery longevity. However, the reduced number of shots per charge is not acceptable to most photographers.

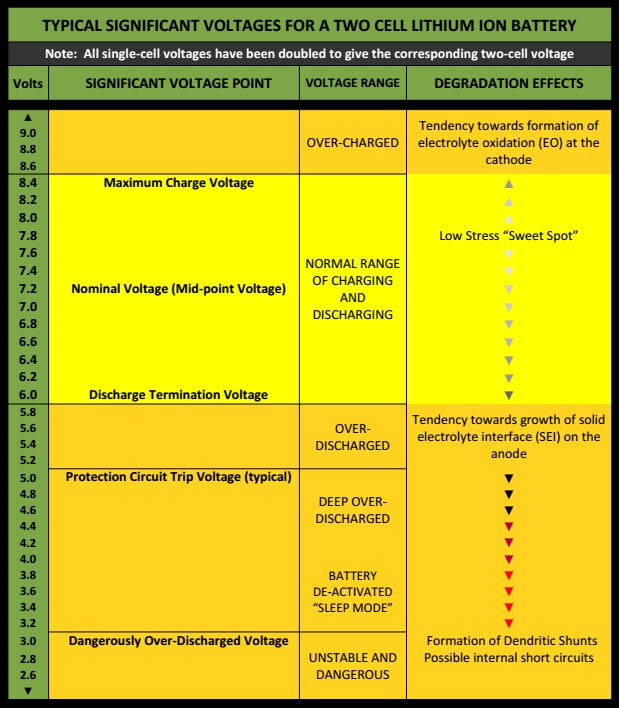

VOLTAGE LIMITS FOR CHARGE AND DISCHARGE

Automatic chargers should implement protections against over-charging, and the camera should implement protections against over-discharging. The battery also has its own internal protective circuit to guard against over-discharging. Limits are according to the following significant voltages:

Although there are automated systems in place to guard against over-charging and over-discharging, poor usage practices can effectively put the battery slightly into the over-charged / over-discharged state. Slight over-charging can result from repeatedly putting an already fully charged battery back on the charger. Slight over-discharging can result from repeatedly turning on again, a camera that has displayed the battery empty sign and automatically switched off.

TEMPERATURE LIMITS

Li-ion batteries are noted for their wide range of operational temperature compared to many other battery types, however, they are very sensitive to temperature beyond that operating range.

As temperatures become elevated, initially the battery sustains internal damage which impacts its long-term performance, then at very high temperatures, the battery starts to sustain damage which can pose serious safety risks. Li-ion batteries contain flammable electrolyte that may vent, and spontaneously ignite when subjected to temperatures above +150℃ or +300°F. When ignited, Li-ion batteries can burn rapidly with flare-like burning effect, and may ignite other batteries in close proximity.

VOLTAGE STABILISATION

After a full charge, the open-circuit voltage of the battery (as checked with a multi-meter) will decrease rapidly in the first 10 minutes and then gradually over the next few hours before stabilising. If you intend using voltage as a guide to battery condition, rest the battery for 90 minutes after charging, before measuring the voltage. The stabilised voltage is a better indicator of SoC than the voltage measured immediately after charge termination, and you are likely to get better power metering by the camera if you begin using the batteries after they have stabilised. This supports the practice where, if you have to charge batteries for a shoot, it is preferable to charge them the night before the shoot, rather than immediately before the shoot.

MEASURING BATTERY VOLTAGE

If you have the requisite background knowledge, and are comfortable with using a digital multimeter (DMM), you can use the battery’s open-circuit voltage as a surrogate for battery state and condition. Since these measurements do not assess the battery under load, they cannot account for load related voltage drop, however they are useful in giving further information for battery assessment and comparison. It should be noted that instantaneous voltages during charging, and instantaneous voltages during discharging display hysteresis. That is, they follow different curves, showing discrepancies in the region of up to half a Volt, with lower voltages presenting for the discharge curve. Therefore, voltages during charging and during discharge are not suitable for comparison.

When doing these static measurements on the battery, the only contacts of interest will be the positive and negative contacts. For measuring the open-circuit voltage, set the DMM to DC voltage measurement, and make contact with the probes for just enough time to get a stable reading. Measurements should be made to the nearest tenth of a Volt.

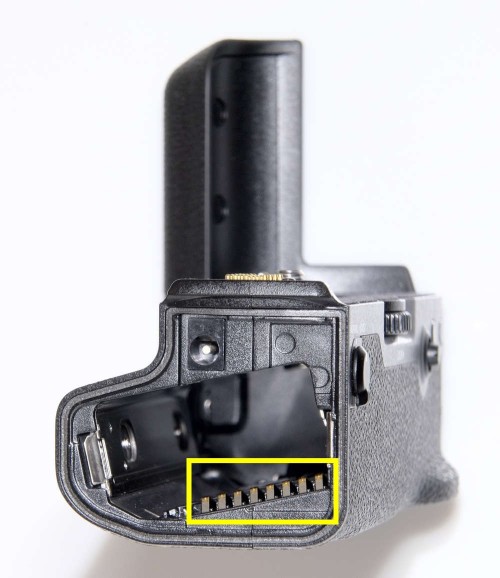

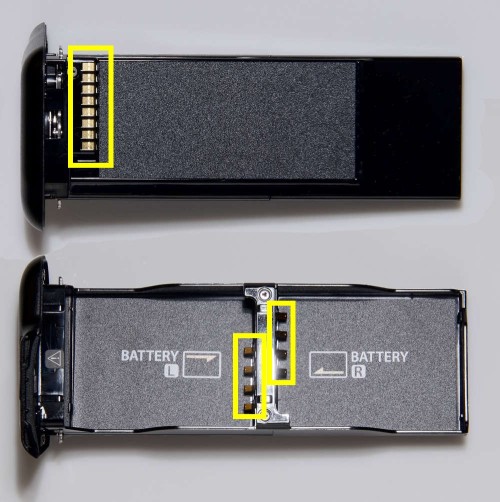

NP-W126 BATTERY CONTACTS

The NP-W126 class batteries have four gold-plated electrical contacts, marked with [-], [S], [T], and [+] symbols.

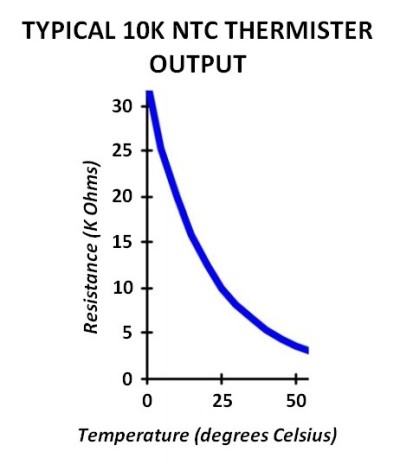

The [T] contact pertains to temperature management, and should connect to an NTC (negative temperature coefficient) thermistor, with a nominal resistance of 10kΩ at 25°C (±5% or better, typical). The resistance of the thermistor drops (with a non-linear output) as temperature increases. [To give an example: The NP-W126S battery was temperature stabilised at the room temperature of 15°. The resistance reading from the thermistor was 13.5 kΩ. Then, the battery was placed under the armpit for 5 minutes, to warm it. After warming it, the thermistor reading was found to have dropped to 9.5 kΩ]. The thermistor allows temperature monitoring while charging. Li-Ion batteries typically increase 5°C (9°F) in temperature during charging, as a normal consequence of the chemical process involved. But, the battery should not be allowed to increase more than 10°C (18°F) during charging, nor is charging allowed at more than 45°C, or less than zero°C, in order to avoid shortened battery life, lithium plating at the anode at sub-zero temperatures, and over temperature hazards such as battery swelling, venting, and thermal runaway.

When attempting to charge the NP-W126 class batteries, in the X-T3 camera, or either of the two Fujifilm chargers, if a resistance indicating a temperature within the safe range is not seen at the [T] contact, then charging is not initiated. (This safety function is also implemented on the Nitecore FX1 USB charger). On non-OEM batteries, the [T] contact is usually just connected to a fixed 10kΩ resister (meaning that it always signals the temperature as OK, even if it is outside the acceptable limits). This allows the batteries to be charged, without adhering to the safe charging temperature protocols.

The purpose of the [S] (probably standing for “Status” or “System”) contact is not openly documented. The [S] contact most likely accesses a simple system indicator, that gives battery information by whether or not a measured resistance exceeds certain thresholds. Such a method is expandable over time, so that if a new further improved battery became available, another higher resistance threshold can be added to the system, to indicate that battery. Note that the X-T3 camera differentiates between “S” and “non-S” type batteries, by interrogating the resistance on this [S] contact.

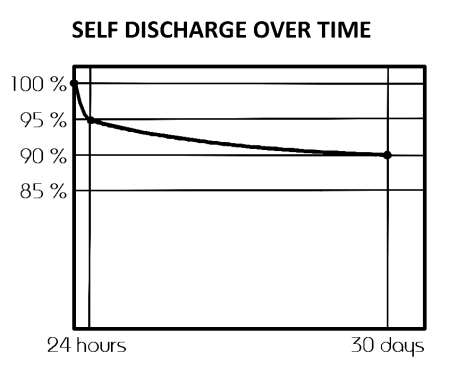

SELF-DISCHARGE

Typical self-discharge rates for Li-ion batteries (at a temperature of about 20°C) are 5% in the first 24 hours after charging, and then 5% per month (this monthly five percent is made up of approximately 2% intrinsic loss, and 3% due to drain by the battery protection circuit).

As a rule of thumb, the self-discharge rate doubles with every 10°C increase in temperature.

PLANNED DISCHARGE

Sometimes, we may wish to intentionally either partly or fully discharge a battery, for example, for testing purposes, or in preparation for storage. The X-T3 camera does not provide a specific discharge function (Some cameras do, for example Samsung NX1). For the X-T3, the best way to discharge the battery is through normal usage, just by taking photographs or video. There may be situations where your purpose is only to take the battery’s SoC just out of the fully-charged zone (one of the more stressful states of battery condition). For example, you may have charged the battery in anticipation that it would be used, but it turns out that you won’t be needing it, and the battery faces an extended period of non-use.

In such a case, you can slightly discharge it by the following method. Put the battery in the currently assigned discharge position (the left-most position if using the battery grip), attach the supplied EF-X8 shoe mount flash unit to the X-T3, and take a few shots using the flash. The EF-X8 has to be used, since it draws its charge power from the X-T3 batteries. (Incidentally, occasional use of the EF-X8 flash, is good for the X-T3’s flash capacitor, and helps to keep it “formed”). Another method is to take some video at a high frame rate and resolution (it doesn’t need to be 4K video). It is not recommended that you discharge by taking long duration continuous-shooting bursts using the mechanical shutter, because this will cause unnecessary wear-and-tear on the shutter, which although rated at several hundred-thousand actuations, never-the-less has a limited lifetime.

STORAGE

Conditions of storage (an extended period of non-use) have an impact on the life expectancy of the battery. The most significant factors are, the battery’s State of Charge (SoC), and the ambient storage temperature. A Li-ion battery’s state of least stress is about 40% SoC at 15°C (59°F). This is represented by 2 bars on the X-T3’s battery level indicator.

DOWN TIME

If the battery will not be used for several days, or even a week, this period can be considered normal down-time, rather than a storage period. The battery can be left in its present state of charge, although leaving it in a fully charged state is not ideal, and should not be a target for a regular down-time state.

SHORT-PERIOD STORAGE

If it is estimated that the battery will be in a storage condition for a few weeks, “half-charged” is an appropriate level. However, it is also OK to leave the SoC at an effectively “flat” level. A battery which has just gone flat (according to the camera), is still well above any damaging over-discharge voltage. An ambient temperature of +15°C is optimal, but since the period of non-use will be short, a storage temperature in the range -10 to +40°C is OK.

LONG-PERIOD STORAGE

If it is estimated that the battery will be in storage for a period of months (this could happen if you were going to be away from home for an extended period of time, and you are taking a different camera with you), it is recommended to have the SoC of the stored battery at 40 – 50%, indicated by between 2 or 3 bars on the X-T3’s battery level indicator. This places the battery in a low stress condition, but also allows for inevitable self-discharge (about 5% per month) to take place, without the battery over-discharging. The battery should not be stored in the camera, due to further discharge by quiescent current. (Quiescent current flows due to the camera awaiting any wake-up signal from the power switch, and also from powering the clock-calendar). An alternative method of assessing a battery’s readiness for storage is by measuring its voltage. A battery in good condition will have a stabilised open circuit voltage of about 7.6 Volts when its SoC is about 40%.

If initially stored at 40% SoC, after about 8 months the battery may be close to flat, so it would be good if the stored battery could be given a part charge (back to 40 – 50%), say about every 3 – 6 months. At any rate, a battery should be charged at least once per year. A storage temperature of +15°C is optimal, but up to +25°C is acceptable, however it is not recommended to store the battery outside the range of 0 to +35°C.

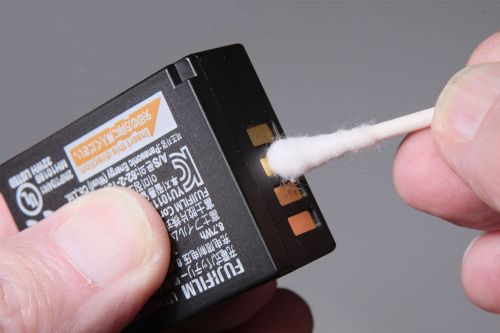

KEEPING CONTACTS CLEAN

Keeping the battery’s gold-plated contacts clean can help attain optimal charging and usage conditions. Contacts can become dirty from inadvertently touching them, or simply by the deposition of air-borne grime (particularly in cities, where the presence of diesel fuel particulates and other pollutants can be significant). A cotton-tip is useful to buff the contact surface. No liquid or solvent should be used.

Keep in mind that there are numerous contacts in the power supply chain, and they all need to be kept clean. However, be very careful not to catch and bend any spring contacts.

IDENTIFYING INDIVIDUAL BATTERIES

For the purpose of battery management, it is useful to be able to identify each individual battery, by labeling them. No stickers should be attached to the sides of the battery, due to the possibility of jamming in the battery chamber. A convenient place to write (using a fine tipped permanent marker), a number, letter or symbol for individual battery identification, is the orange orientation patch (square or circle) at the end of the battery. The manufacturing year and month code letters are convenient identifiers. Unless several batteries were purchased at the same time, and they came from the same production batch, the production codes are likely to be unique, for each of your batteries.

If you have to use non-OEM batteries, you can put a small sticker in the same position as the NP-W126 class battery’s orange orientation patch. Since you probably won’t know the production date of the battery, you can arbitrarily assign it a production date three months prior to the purchase date, (this allows for some shelf time with the vendor, before purchase). You can give it year and month code letters, according to the Fuji system, so that any management records follow a consistent method.

DETERMINING THE BATTERY’S END OF LIFE

A battery is effectively dead when the photographer rejects it due to poor performance. A battery that has been used properly does not suddenly cease working, but it does eventually reach a point where its performance no longer meets the requirements of the photographer. This point will differ slightly from person to person, depending on their usage style and workload demands. Specific signs of a dead or dying battery are:

• Uncharacteristically long or short charging times

• Very rapid self-discharge

• Noticeably decreased number of shots per charge.

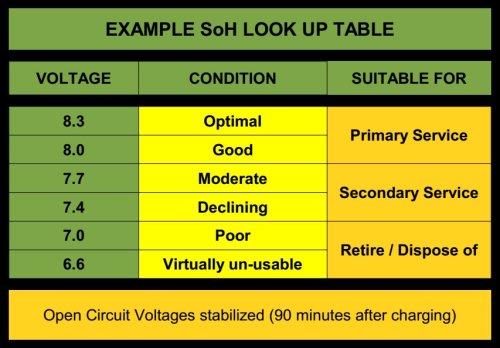

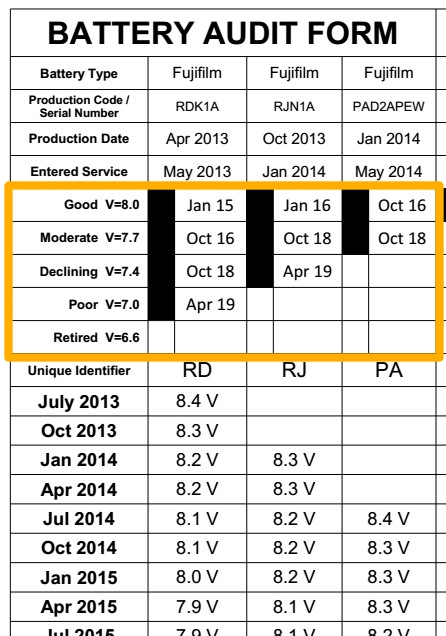

SoH LOOK-UP-TABLE

Based on the typical signs of a dead or dying battery, the photographer will develop a feeling about how a particular battery is doing. However, this type of assessment can be very subjective. A more objective criteria of the battery life condition (State of Health – SoH) can be obtained from the stabilised (90 minutes after-charge) open-circuit voltage. It is not possible to give a universally applicable look-up-table (LUT), because battery usage routines (as well as user expectations), and local environmental conditions, will cause variation in the typical voltages reflecting the various states. However, it is possible to compile your own personal LUT over time, if you are prepared to take measurements and keep records. A SoH look-up-table, may be similar to this:

This method is useful if you want to keep records, for comparison, of battery condition at regular intervals, because it yields a number.

This method is useful if you want to keep records, for comparison, of battery condition at regular intervals, because it yields a number.

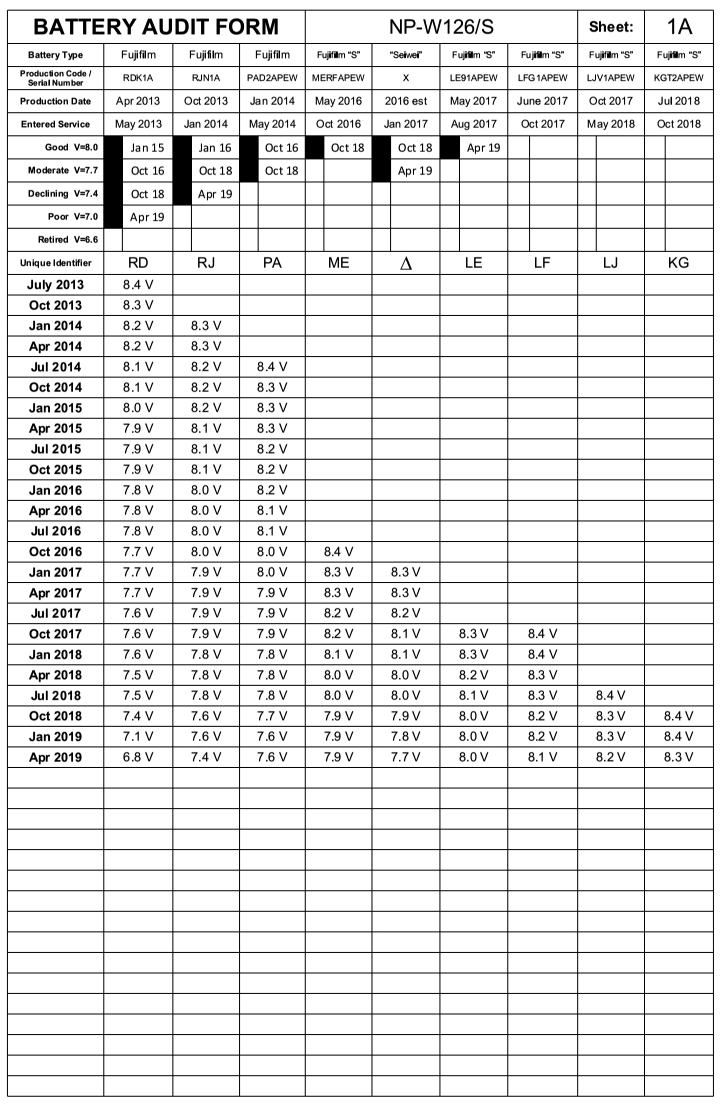

BATTERY AUDIT FORM

A convenient way to keep records of battery condition is a battery audit form. This could be either on paper, or a computer spreadsheet. On the form, you record the open circuit voltage (90 minutes after charging), of each battery.

This is done at regular intervals; three monthly (that is, four times a year), would be an appropriate interval. Just do it sometime during the designated month – it is not necessary to do it on a specific date. The form also allows you to record the reaching of significant voltage thresholds (based on the SoH look-up table).

A PDF file of the audit form can be downloaded here: Battery-Audit-Form.PDF

PRIMARY AND SECONDARY BATTERY SERVICE

Batteries that are beyond the two year or 300 cycle stage, although no longer in their prime condition, are still useful. While the best batteries are kept for operating the camera at its top performance (primary service), the aged batteries can be assigned to secondary service tasks. Such tasks include:

• Back-up batteries

• Batteries for short or low shot count sessions

• Hold-over batteries

Hold-over batteries are useful if you recharge all batteries directly after a shoot, in readiness for whenever the next shoot will occur. If the camera is left unused for days or weeks, the first battery in the discharge sequence will lose some of its charge (due to quiescent current, waiting for power-up signal, and maintaining the clock and calendar system). That same battery would maintain more of its charge over the same period of time, if not left in the camera. To avoid this “stand-by” discharge of the battery, when you are not using the camera, you can replace the first battery with an old battery, and just swap in the newer (still well charged) battery, before the shoot.

JUST IN CASE vs JUST IN TIME

“Just in case” and “Just in Time” (JIT), indicate two different approaches to what “triggers” you to recharge your camera batteries. Should you recharge them immediately after a shoot (so that they are ready to go), or should you leave them in their post-shoot state, and recharge them just prior to the next shoot? There is no universally correct answer, because it will depend on your usage style, workload demands, and also your ability to know in advance when the next shoot will be, or even to exercise your own discretion about when shoots will occur. Keep in mind that, when a Li-ion battery has gone flat during a shoot, there is no problem leaving it in that state for some days, or even weeks (just let it have some “down time”). A Li-ion battery is very different from a lead-acid car battery, which should not be left in a discharged state. However, as to the long term affects on battery life, it is probably more beneficial to, where possible, let the immanence of usage be the trigger for recharging (just in time), rather than letting the conclusion of usage be the trigger for recharging (just in case). This is because, with charging directly after the shoot, if you wait some time before the next shoot, the battery has been left longer in a fully charged state (not optimal for battery longevity), and you are likely to give the batteries a top-up charge before the next shoot anyway. This results in more charging than is absolutely necessary. Furthermore, Li-ion battery service life benefits from sustained (many hours to days) relaxation periods following discharge and before re-charging.

BATTERY CASES

Battery cases are useful in order to protect against accidental shorting of the power terminals, and give a convenient means of distinguishing between charged and discharged batteries. Also, in accordance with IATA regulations, pouches or cases are necessary if spare batteries are to be carried (in carry-on baggage only) while traveling by air-transport. New NP-W126S batteries, when purchased as an accessory, are supplied with a plastic soft pouch.

However, if you would like a hard case, those designed to fit the Nikon EN-EL9 battery, are suitable (although slightly longer than necessary). You can cut some dense (non-conductive) foam plastic to fill the extra length, and stop the battery from rattling in the case. The internal dimensions of any suitable battery case, need to be at least 47.5 x 36.5 x 16 mm.

For working in harsh environments, sealed weather-proof cases are also available.

IDENTIFYING CHARGED / DISCHARGED BATTERIES

If spare batteries are kept in a pouch, or battery boxes, a simple method of distinguishing between charged and discharged batteries, is by inserting the batteries with the contacts facing either inwards or outwards, to signify charged or discharged. Alternately, if you use many batteries, you can have two battery pouches, one for charged batteries, and the other for discharged batteries.

LI-ION FIRE HAZARD

If a Li-ion battery develops an internal short-circuit, this can be the prelude to a thermal-runaway event that eventually causes the battery to rupture or vent, and spontaneously ignite. Other triggers for catastrophic battery events include: faulty charging, accidental short circuit by contact with metal objects, use of the camera or batteries outside of allowable limits, and heavy trauma to the camera. The fuel for the ignition is the electrolyte content of the battery, rather than lithium metal. Although lithium metal reacts violently with water, lithium-ion batteries, contain very little metallic lithium. As a consequence of the sparse metallic lithium content, water is a suitable and recommended extinguisher for burning Li-ion batteries, such as the NP-W126 types. There are two goals in extinguishing a Li-ion battery fire: First, to extinguish the initial fire, and second, to cool the immediate surroundings to avoid the ignition of other Li-ion cells. It should be remembered that a single NP-W126 type battery contains two Li-ion cells, so the X-T3 camera and grip (3 batteries in total) holds 6 cells, and each one will ignite in series (with a delay of between several seconds up to several minutes between each ignition), if the local temperature is not significantly lowered. Water is the best medium for lowering the temperature. However, covering the extinguished batteries, even with ice cubes, is not recommended, because it tends to form an air pocket which traps and retains the heat, leading to re-ignition.

Section – F

POWER MANAGEMENT SETTINGS

Mirrorless cameras, such as the X-T3, are inherently more voracious for power than DSLR’s. The specific difference in power requirements is the mirrorless camera’s use of an electronic viewfinder (EVF), or continuous use of the LCD monitor. The key to getting power consumption that approaches that of the DSLR, is to configure the EVF and LCD monitoring system, so that they are not turned on more than they need to be.

VIEW MODE SETTING

The most power efficient View mode option is “EVF ONLY + Eye Sensor”, because it results in the viewing system being on for the least possible time. “Putting your eye to the viewfinder turns the viewfinder on; taking it away turns the viewfinder off. The LCD monitor remains off”. The view modes can be cycled through by pressing the view mode button on the right side of the EVF housing.

AUTO POWER OFF SETTING

Try to set the Auto Power Off function to the shortest interval that you can comfortably work with. Wake-up from automatic power-off is achieved in less than one second by simply half-pressing the shutter button.

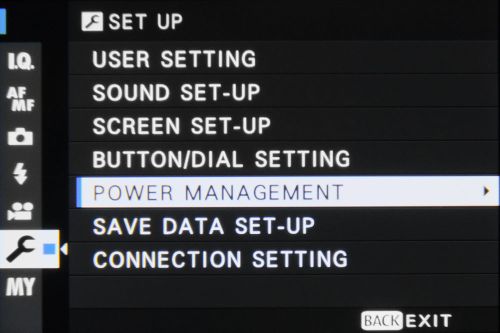

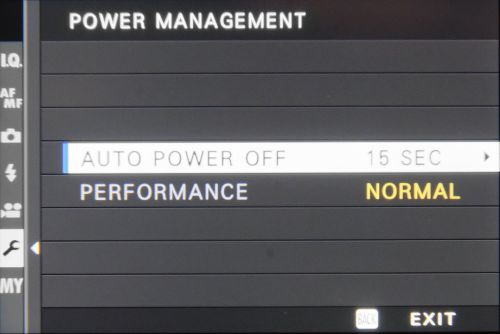

POWER MANAGEMENT MENU

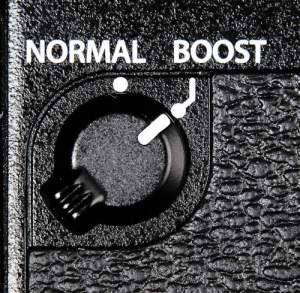

Auto Power Off and Performance settings are accessed through the Power Management sub menu of the Camera’s Set-Up menu. For convenience, the Performance (Boost) setting can be assigned to one of the function buttons. However, this is not necessary when the optional grip is used.

When the grip is attached, the “Performance” menu option, is greyed out, and unavailable, (to avoid selection conflicts) because the grip has its own dedicated performance (normal or boost) switch.

BOOST MODE

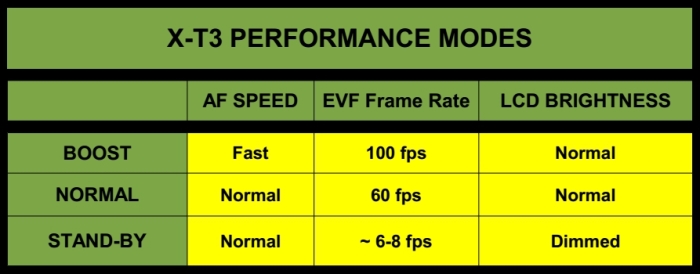

Unlike the X-T2 and X-H1 cameras, the X-T3 is able to realise top performance even without the optional battery grip. The high performance mode is called boost mode. When the highest performance is not needed, the camera can be set to Normal mode. In Normal mode, to conserve battery power, after ten seconds of inactivity (no button, dial, or touchscreen activation), the displays revert to a stand-by mode (low brightness, and very slow frame refresh rate). The display leaves this stand-by mode if there is a control activation event, or if the power mode is switched to Boost. There are no menu options for modifying this behaviour. However, if you are not using functions that that take a high power drain (continuous auto-focus, continuous high-rate stills shooting, and high resolution video), then leaving the camera in Boost mode should not produce any significant run time deficit.

According to the advisory message displayed when non-S type batteries are loaded, “Boost mode function is restricted”. The exact restrictions, for this situation, are still being compiled. (I will update this guide, as further information becomes available).

Section – G

EXTERNAL CHARGERS

BC-W126S / BC-W126

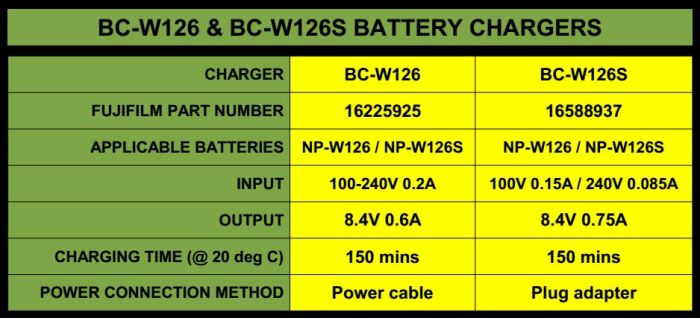

The release of the X-T3 was accompanied by the introduction of a new battery charger. The newer BC-W126S is the charger generally supplied with the X-T3 camera, although, the Owner’s Manual (page xix) states: “A BC-W126 battery charger may be supplied in place of the BC-W126S in some countries or regions”. The two chargers are interchangeable, and either charger can be used for either battery (NP-W126 or NP-W126S).

The two chargers differ in two main points: The method of connecting to the mains supply, and the slightly increased maximum output current by the BC-W126S. (Does the newer charger differentiate between the older NP-W126 and the newer NP-W126S batteries, when charging them? I don’t know yet, but keep in mind that the two battery types have a different resistance level on their [S] contacts, so the charger may differentiate, and charge them slightly differently. But, that’s pure speculation. I will try and test this when I make a break-out box for the charger.)

NON-OEM CHARGERS

Some non-OEM chargers can deliver functionality and flexibility not available from the standard supplied charger. Beyond cost, you should consider how the charger fits in with your workflow and approach to photography. It is also important to remember that the quality of the charger can have a significant effect on short-term and long-term battery performance and service.

UNEXPECTED INTERACTIONS

Power banks utilise a voltage converter circuit to change the battery voltage to the required USB supply voltage. Power is lost due to the conversion process, so it is typical for power banks to turn off the conversion circuit, if the power bank senses that the connected device no longer requires power. (The power bank will assume this if current draw falls below a certain threshold). At the same time, some chargers (typically, “smart” chargers), may momentarily suspend charging at regular intervals, in order to take measurements of the battery’s state of charge. If the power bank’s checking of the current flow, and the charger’s checking of the charge state happen to coincide, the power bank may momentarily shut down. After the smart charger’s state of charge check, the power bank will sense the charger’s need for power, and power up again. This gives the unexpected behaviour that the pair of devices “power off” momentarily, and then resume operation. The momentary power interruption does not affect the charging of the batteries, but it does have the effect of causing the charger’s count of accumulated milli-Amp hours (mAh) to reset back to zero, each time a power interruption occurs. I have experienced such an effect when powering the Nitecore FX1 with some power banks (including Tomo). However, if you place a USB power monitor in-line between the power bank and the charger, it can sometimes act as a buffer, so that power interruptions tend not to occur, and the effect of the mAh count resetting is avoided.

OVER-TERMERATURE PROTECTION

One very important factor, when considering non-OEM chargers, should be, whether the charger implements any kind of temperature monitoring, while charging. This will mean, either the ability to monitor the NP-W126S or NP-W126 battery’s thermistor (on the battery’s [T] contact), or the charger having its own built-in temperature sensor. Over-heating the batteries while charging will produce cumulative damage to the batteries (noticeable as as a decline in the battery’s performance, or as swelling, or venting of electrolyte reduction gases). Two third-party battery chargers that are known to implement battery temperature management are, the JJC DCH-NPW126 dual slot USB charger, and the Watson Duo Charger, dual slot AC charger (both chargers utilising in-charger battery temperature sensors). The Nitecore FX1 dual slot USB charger (utilising a third battery contact to monitor the battery’s thermistor output), reports the internal temperature of the genuine Fujifilm batteries (not of non-OEM batteries, however), and it should be noted that it does not terminate charging if the temperature exceeds the allowable temperature range – the user must do that.

Note that if the battery is non-OEM, and does not implement a working thermistor, then a charger’s thermistor monitoring function will be ineffective, since there is no genuine temperature information to monitor (only the battery’s fixed 10kΩ output by the [T] contact, which flags a “within acceptable temperature range” status, required by the Fuji charger before it will initiate charging).

Section – H

X-T3 USB PORT

The X-T3 camera has a USB type-C (USB 3.1 Gen 1) connection port. As well as its data transfer function, the port can also be used to input 5 Volt power for charging the battery in the camera body, or to assist powering the camera’s operation.

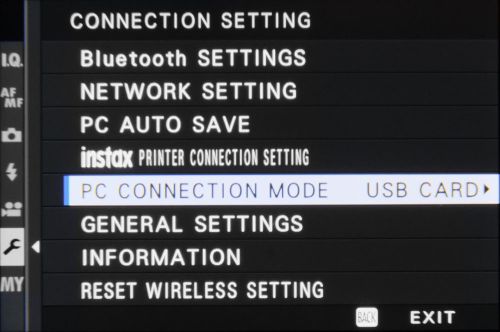

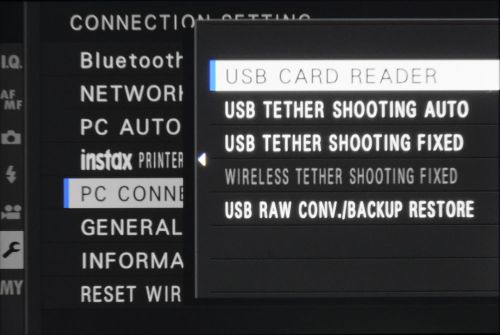

MODE SELECTION

Because the X-T3 has tethered shooting functionality, connection of a USB cable can trigger unexpected camera behaviour, if the Set Up Menu’s “PC Connection Mode” setting is not appropriate. How the 5 Volt supply is utilised depends on camera mode (off, shooting, or playback), as well as the PC Connection Mode menu settings. If not tethering to a computer, a relatively trouble-free setting is “USB Card Reader” mode.

CONNECTOR TYPES

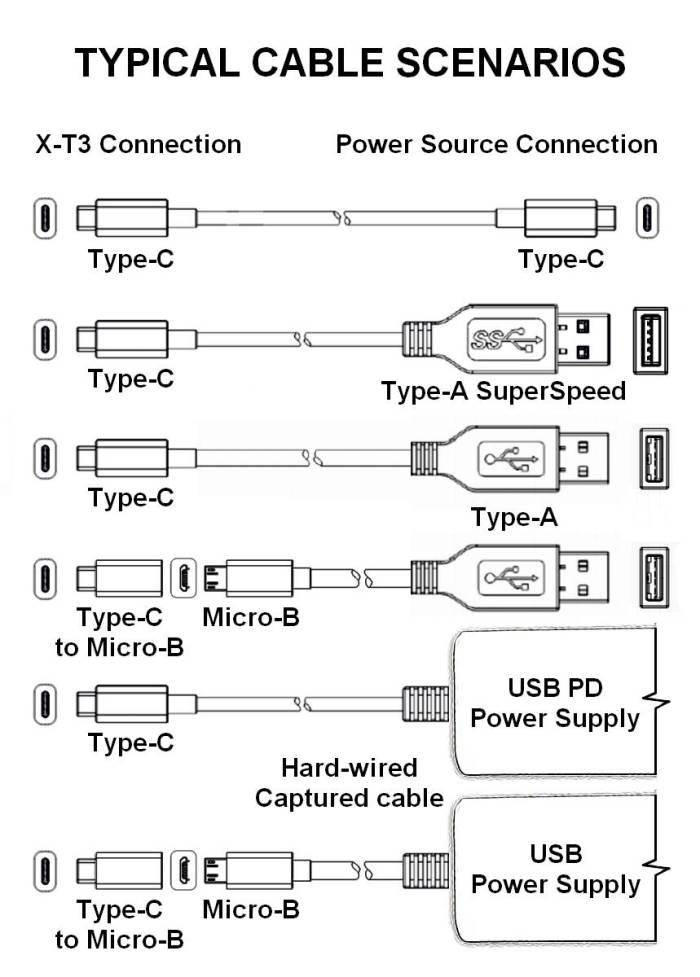

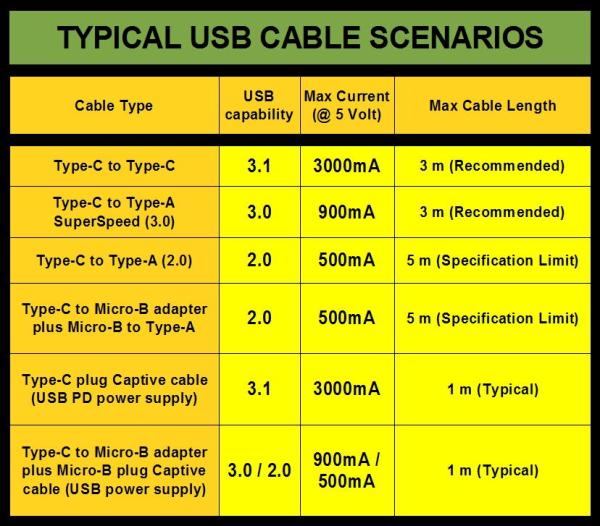

The USB socket accepts a USB type-C plug. However, depending on the type of device used for charging, the cable could be either a USB type-C to type-C, or a USB type-A to type-C cable.

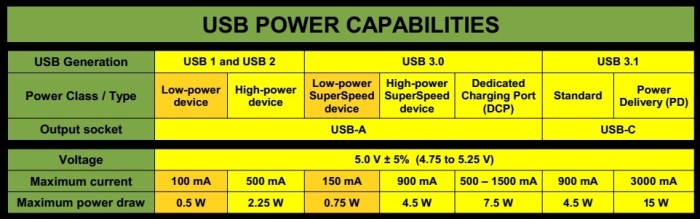

According to USB standards, the X-T3 is considered a high power device, since it requires at least 500mA from the USB supply.

Since all of the USB standards from 2.0 onward can deliver at least 500mA (composed of an allowed maximum of 5 x 100mA load units, as defined under the USB standard), most USB compliant outputs meet the X-T3’s charge requirements. It is best to use the highest current-capability port for powering or charging. If the device manufacturer has implemented port colours, they can be a convenient method of differentiating between the power capabilities of different type-A port options, on a desktop or notebook PC. Port colours are not mandatory, however, members of the USB Implementors Forum (USB-IF), tend to assign the colours consistently. Of course, if the power output port is a type-C port, you can assume that it is USB 3.1 standard.

If you have previously been working with USB 2.0 and 3.0 charging methods, and using type-A and micro-B connectors, the X-T3’s adoption of the type-C connector does not mean that your previous charging system needs to be replaced. As long as the system terminates in a type-C connector, for connection to the X-T3, you can continue as before.

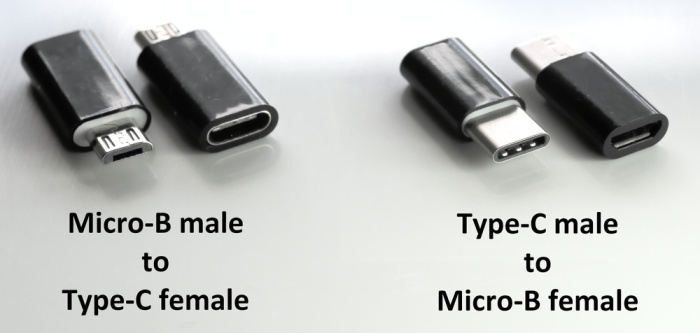

It should only be necessary to acquire a new type-A to type-C cable, or even a micro-B to type-C adapter, if a charger has a fixed cable (“hard-wired captured cable”). These plug adapters can also be used on legacy cables (earlier generations than type-C). The converse scenario might occur if you have acquired a USB power supply with fixed type-C cable, and you want to charge a power bank, or use a USB battery charger, that only has a Micro-B input port. In this case, a type-C to Micro-B adapter with the genders reversed can be used to make the connection for charging.

Please be very careful. These adapters are very small, and therefore dangerous to leave within reach of infants and small children, who might put them in their mouth, with the risk of choking.

It should be noted that the USB type-C standard implements two Control Channel pins (CC1 and CC2) on the type-C connector, and these are used to establish and manage the Source-to-Sink connection. Since legacy cables and connectors do not implement these Control Channel lines, attaching type-C adapters to a legacy cable will not convert it to a “full featured” type-C compliant cable. However, it can still produce a functional USB power transfer cable.

USB “POWER DELIVERY”

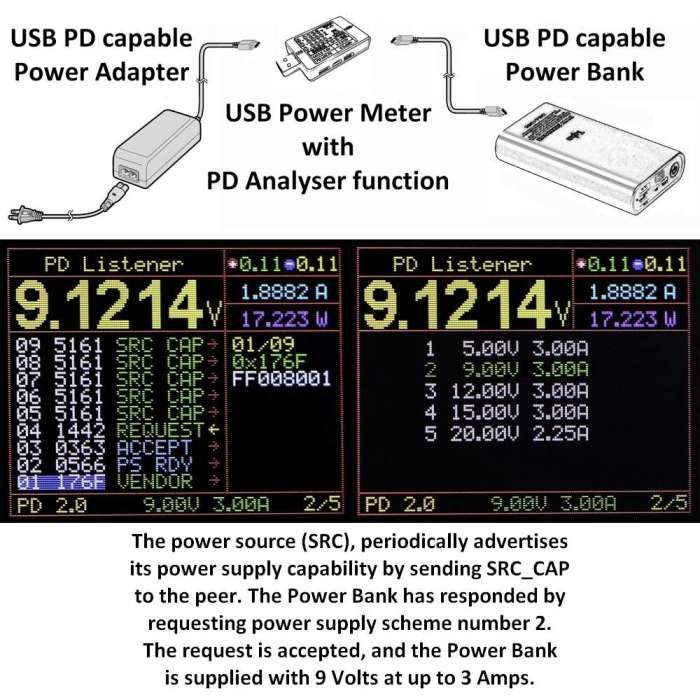

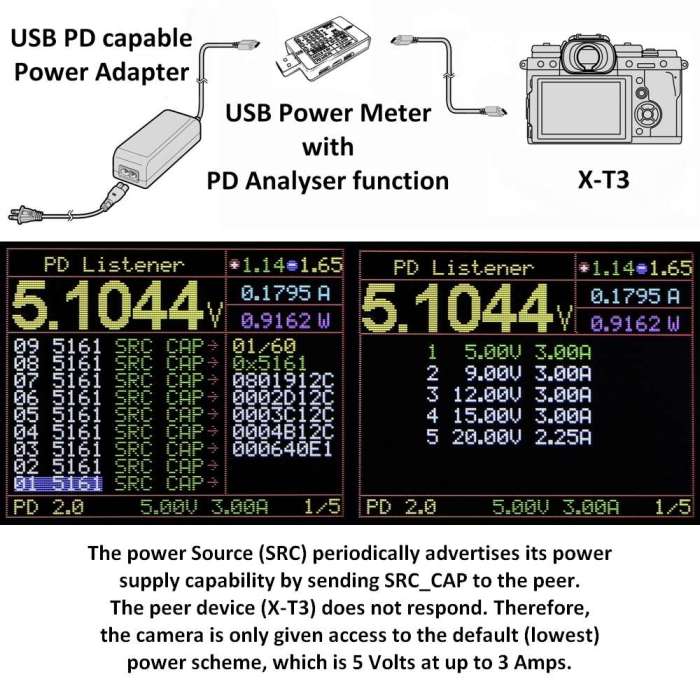

What happens if the X-T3 is connected to the USB PD (Power Delivery) port of a computer, power bank, or to a USB PD power supply? We know from experience that if the X-T3 is connected to a USB PD power supply with a hard-wired captured cable (so that there is no doubt that the cable is PD aware, compliant, and capable of conducting high currents), the X-T3 will draw 5 Volts at up to 1500mA for charging, or operation in video mode. In stills photography operation, the current draw is considerably less. In contrast to this, when the same USB PD power supply, is used to charge a 20000mAh PD power bank, the power bank draws 9 Volts at 2000mA.

Because the X-T3 has a Type-C port (which people often associate with PD), and because Fujifilm has recommended external USB power via the Anker PowerCore powerbanks (which support PD), there might seem to be the implication that the X-T3 supports elevated power levels via the PD functionality. However, as far as I am able to establish, the X-T3 does not require or negotiate elevated PD power levels (that is, power above the PD default), although it is compatible with USB systems that do support PD. So, if a charger, power bank, or PC conforms with the general USB specifications, it can be used to supply USB power to the X-T3, whether the device supplying the power supports PD or not. The following (printed in red) is simply to explain how PD works, and why we can say that the X-T3 does not negotiate elevated power levels.

USB Power Delivery (PD) is designed to co-exist with standard USB Battery Charging implementations. The USB Power Delivery protocol requires the following steps: Connection, Default Operation, Discovery, Negotiation, and Contract Operation. When a USB host and device are first connected, the initial operating conditions are the USB Default Operation, which assumes a DFP (Downstream Facing Port) supplying vSafe5V (a voltage level of 5 Volts, which is safe for all USB devices) over the VBUS line, and a UFP (Upstream Facing Port) consuming power from the VBUS line. In the case of USB PD compliant equipment, once these default conditions are set, a Discovery process can begin, if the connecting cable meets requirements. Discovery comprises the exchange of structured VDMs (Vendor Defined Messages) resulting in identification of the Port Partner, its supported SVIDs (Standard / Vendor IDs) and Modes. After the Discovery process, power Negotiation begins. The Source (power supplier) advertises its capabilities, and the Sink (device which will consume the power) requests one of the advertised capabilities. Then, the Source acknowledges the request and alters its output to satisfy the request. The result of this process is a Contract for power delivery/consumption between the two port partners. The contract specifies both power level and direction between the Port Pair. Typically, the contract continues until the ports are disconnected.

Cable specifications are an important part of the USB PD protocol, because, as well as the power source being able to supply the required power, a connected cable must also be able to carry that supplied power. Higher power requires a higher specification cable, for instance, heavier gauge conductors. Standard Type-C cables (with no built in circuitry) should support up to 3 Amps of current by default. But in order for a USB PD compliant source to advertise capabilities greater than 3A, the Type-C cable must be an Electronically Marked Cable Assembly (EMCA). The electronic marking is accomplished by embedding a USB PD controller chip into the plug at one or both ends of the cable. The cable controller stores configuration data related to the identity and capabilities of the cable. Electronic marking is needed in a Type-C Cable when VBUS current of more than 3 Amps is required. Of course, an Electronically Marked cable will be more expensive than the corresponding un-marked cable. The benefits of an Electronically Marked cable are not relevant for the X-T3 camera, since it does not require current at higher levels than the 3A default. The next step up in current rating is 5A, and since 5 Amps at 5 Volts is 25 Watts, that already exceeds the X-T3’s 18 Watt power rating. The simple “un-marked” type-C cables are sufficient for the X-T3’s power requirements. Importantly, after the setting of the USB Default Operation, if the PD protocol cannot be established, then the power remains at the default vSafe5V, which should mean there is no risk of damage to equipment. In this way, interoperability between PD capable equipment and legacy USB equipment and cables, is maintained.

In practical terms, the significance of USB PD for the X-T3 camera seems to be the ability for the camera to draw 1500mA at 5V (even with just a standard type-C cable), compared to the typical 900mA at 5V from the USB 3.0 / 3.1 bus. This increase in current represents a modest improvement. Note however, the USB 3.0 Dedicated Charging Port (DCP), could already deliver 1500mA. Although the USB PD standard allows, in principle, power delivery up to 100 Watts, the X-T3’s ability to consume power is limited, by its highest battery-safe C-rate while charging, and in operation, by its maximum working temperatures, since more power produces more heat. Increased heat, without a corresponding ability to dissipate heat at a higher rate, would be a typical precursor to camera lock-up events. Remember that the X-T3 is rated at 18 Watts. So, even with USB PD, do not expect the X-T3 to be able to benefit from more than 5 Volts at 3 Amps, maximum (15 Watts).

In summary, it would seem that the X-T3, even in a fully PD compliant connection context, does not exploit the possibility of negotiating elevated power levels through the PD protocol, probably because the camera does not need those elevated levels.

The camera is, however, able to gainfully utilise the increased default power level offered by PD capable equipment (maximum current of 3000mA, rather than 900mA), and this is why connection to a PD capable port (marked with the letters “PD”), is both advantageous, and preferable to connection through a standard port. If your goal is to get maximum and continuous power for video production, an alternative option is to use V-Mount batteries with D-Tap (as explained in Section J – “DC Coupler”).

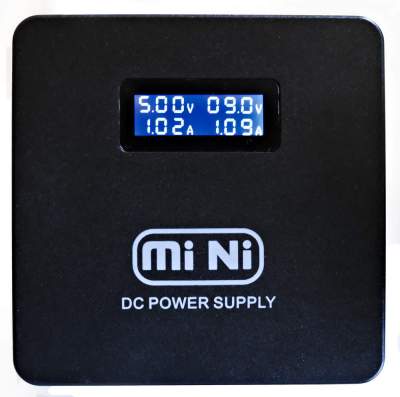

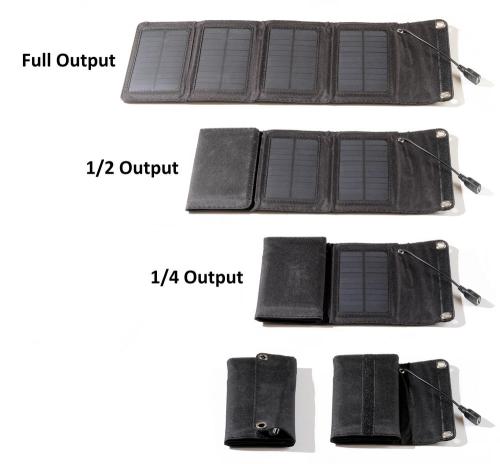

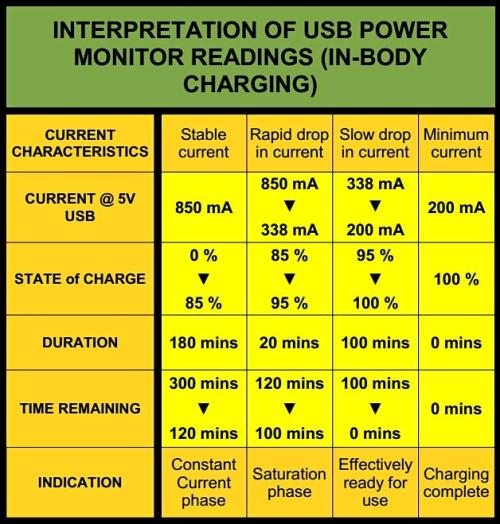

USB HUBS NOT SUITABLE